By Robert L. Reid

Developing underwater habitats and other facilities involves challenging and unique engineering designs. With ocean resources worth trillions of dollars, the demand for such undersea efforts is likely only to increase.

“The future is blue,” declared a November 2022 report of the selfsame title on the United Nations Development Program’s website. And while that report specifically discussed the island nation of Fiji’s “blue economy” — involving the sustainable use of ocean resources — the same principles and potential of underwater development can easily be applied to other projects worldwide.

For civil engineers, the specifics of a blue built environment manifest themselves in a wide range of structures, some only partially submerged, others completely underwater and accessible only by submarine or scuba gear. These include large-scale aquarium exhibits, underwater restaurants and hotels, underwater research facilities, and even long-term submerged habitats.

Some of these structures have been in use for decades, others are fairly new, and some represent possible future development. But all must accommodate the challenges of an environment in which humans cannot survive without precise and innovative engineering designs.

Encountering aquariums

For many members of the public, the first, and perhaps only, place they might encounter underwater engineering is at an aquarium. Here, enormous acrylic windows — formed from multiple large segments that are fused together at the project site, reaching as much as 65 ft in height and 100 ft in width — provide views into huge pools filled with millions of gallons of water. Clear tunnels also let visitors walk through these underwater worlds.

Although such settings can feature elements common to any engineering project — including concrete framing and the use of rebar — the designs of large-scale aquarium exhibits also present many unique, highly specific challenges. One of the most significant is that the “design load is there all the time,” notes Michael Leonard, P.E., S.E., M.ASCE, the president and owner of MLA Engineering LLC in Seattle. “Unlike most buildings, where you design for a transient live load, ... aquarium water is exerting design-level forces from all directions, all the time.”

Plus, these structural systems must also be leakproof — despite often having multiple pipes and other penetrations for the aquarium’s life support systems and other equipment piercing the watertight reinforced concrete, Leonard says. The concrete must develop small cracks, as all reinforced concrete must, to transfer the internal tension stresses into the rebar, he adds. But the concrete mix — which typically features low water-cement ratios and integral pore-blocking admixtures — and the arrangement of rebar must be designed so that the cracks remain microscopic in width to prevent leaks.

Engineers can accomplish this in several ways, such as by adding more closely spaced rebar — perhaps 50% more than for comparable loads that do not involve water, Leonard explains. Engineers can also tightly control heat gain during cement hydration, use water-reducing agents in the concrete mix, and specify curing periods and methods that reduce water evaporation.

Leonard, whose firm has designed multiple aquarium projects around the world, says engineers also must understand the differences between aggregates that are used in concrete in various countries. The porosity of those aggregates is especially critical because it can affect the concrete porosity — and therefore the potential for leakage — in the finished material. Engineers must also know the availability of materials and differences in construction practices on international projects.

Regarding the large acrylic windows and acrylic tunnels for aquarium exhibits, the design must consider the transfer of large forces at the point where the acrylic panels bear against the concrete framing, Leonard says, while the detailing of rebar and the placement of the concrete must provide a crack-resistant, well-consolidated, and watertight system.

The windows and tunnels are held in place largely by the pressure of the water itself, although waterproofing sealants can help secure this glazing. But temporary external clamps are often used to hold the window and tunnel acrylic sections when filling or draining the exhibits. Engineers must also design for potential buoyancy and uplift forces, which can occur, for example, when a tunnel cross section has an arc that exceeds 180 degrees and is surrounded by water exerting pressure in multiple directions, Leonard says.

Designing to dine

At select destinations, the public can also access underwater restaurants and even hotels that present similar engineering challenges. Mike Murphy, a civil engineer in New Zealand and now retired, designed what is considered the world’s first underwater restaurant: Ithaa, near Rangali Island in the Maldives, which opened in 2005.

Supported on four large steel pipe piles vibro-hammered into the seabed 5 m beneath the surface of the water, Ithaa features a steel structure weighted down with concrete and sand ballast and topped by a 5 m wide acrylic arch. Accessed by a jetty from the island and an enclosed stairwell, the restaurant “had to accommodate all possible load combinations induced by the tidal rise and fall, wave action, different pressures while sinking the unit, and even an allowance for future sea level rise from global warming,” according to the website of Murphy’s company, M.J. Murphy Ltd., an Auckland, New Zealand-based design consultancy.

The website remains active, even though the firm shut down following Murphy’s retirement in 2019.

Murphy has designed other underwater facilities in the Maldives, including a larger restaurant known as 5.8, given that name for its depth in meters beneath the waves, as well as an underwater villa known as Muraka that features a submerged main bedroom covered by an acrylic dome. The engineering challenges of submerged spaces begin with the site conditions, Murphy explains, which preferably will be in a coral reef or protected harbor with a low tidal range of less than 1.2 m between the high and low spring tides.

“The greater the tidal range, the taller we must make the stairwell (used to access many underwater habitats), which in turn induces more off-balance upwards buoyant forces in the structure,” Murphy says. Because these stairwells extend above the water, they are the part of the submerged structure most affected by wave forces. Consequently, a circular or oval design is best for such accessways because a streamlined shape will reduce the lateral forces on the stairwells, Murphy says.

Engineers need to calculate the center of gravity and the center of flotation of an underwater facility to determine how stable the structure will be in the water before it is submerged, especially to determine if it might tilt or roll over. Murphy, who also designed numerous aquarium windows and tunnels, says his projects featured acrylic thicknesses that range from 40 mm to as much as 300 mm, although he knows of other projects with windows up to 600 mm thick. These windows are typically sealed with a special silicone sealant rated for underwater use that varies in its applied width from 20 mm to 30 mm, depending on the size of the window and the water pressure.

The sealant, however, comes with its own problems. On Ithaa, “we found that some fish were actually nibbling and eating” the sealant while maritime worms were burrowing into the silicone, Murphy says. As a result, all exposed silicone joints are now protected by a thin cover strip of acrylic.

Contending with rough seas

Although most underwater restaurants are found in warm — often tropical — settings, there is at least one striking exception. In the southern part of Norway, in a region known for cold, harsh weather and rough seas, a structure that resembles a large, somewhat rounded concrete box, measuring roughly 40 m long, 12 m wide, and 20 m tall, looks as if it slid off the land and dropped partially into the sea. But this is no accident. Instead, it is the carefully engineered restaurant called Under, which opened in 2019 in the municipality of Lindesnes.

Developed by a local hotelier who wanted to attract more tourists to the area, Under was designed by the Norwegian architecture firm Snøhetta, of Oslo, and engineered by Asplan Viak, based in Sandvika, Norway. The restaurant was constructed in an open bay off the North Sea, its front edge extending into the water to a depth of roughly 5 m. The underwater portion of the structure features a large acrylic window at the front that measures 11 m wide, 3.5 m tall, and 270 mm thick, says Erlend Stien, an Asplan Viak construction engineer.

The structure was cast on a barge near the site where it was submerged and then lowered by crane into the water — a challenging procedure that required close attention to the barge’s center of gravity because “they had to fill up different chambers with water (and) pump it in and out to regulate the barge to stay in the right position,” Stien explains.

Under is secured to a concrete platform on the seabed by steel piles — roughly 20 m long, some of which slant by as much as 45 degrees off the vertical — to prevent the structure from moving sideways or outward and back, Stien says.

The initial presence of moving water beneath portions of the structure created dynamic pressure and uplift concerns and eroded the sand beneath it, notes Terje Raanes, an engineer and leader of Asplan Viak’s construction department. These issues were resolved by installing a series of boulders around the base of the restaurant, Raanes explains.

Asplan Viak collaborated with CoreMarine, an offshore installation and operations firm that is based in Australia. CoreMarine conducted hydrodynamic analyses, ballasting and stability analyses, and other services, including computer simulations on the wave load forces that Under would face, says Stien.

Because part of the restaurant is underwater and part is above, the structure encounters a unique set of thermal forces, Raanes says. The submerged portion never experiences temperatures below 0 C while the exposed upper portion can face temperatures as low as minus 20 C, which “loaded the construction in unusual ways,” Raanes says. In addition, the upper portion is exposed to wind, snow, and ice loads, all of which had to be taken into account for that part of the structure.

To accommodate the potential for condensation to form inside the structure, the team carefully designed the ventilation and drainage systems.

Staying overnight

People who wish to spend longer periods around aquatic life than just the time it takes to eat a meal or stroll through an aquarium can stay the night, or even multiple nights, in submerged hotel spaces. Besides Muraka and Ithaa, which can temporarily be converted into a luxury bedroom, there is an underwater habitat that originally served strictly as a scientific research facility but now welcomes guests who want an overnight stay roughly 22 ft beneath the waters of a private lagoon.

Known as Jules’ Undersea Lodge, the Key Largo, Florida, facility is accessible only by scuba divers. (For noncertified divers, the parent organization, the Key Largo Undersea Park, offers a quick scuba diving course.)

Originally known as La Chalupa, the habitat was designed to be mobile, notes Ian Koblick, the founder and chair of the Marine Resources Development Foundation, also in Key Largo, which constructed the original habitat and later helped convert it into the undersea lodge.

It features two steel cylinders inside a bargelike structure that can be towed from site to site, with adjustable steel legs to accommodate uneven surfaces on the seabed. Each cylinder is roughly 19 ft long and 8 ft in diameter. The overall habitat features living space, bunks, a marine toilet, and other amenities for up to four visitors.

An umbilical connection to a support vessel on the surface powered La Chalupa’s life-support systems, communications, and electricity. Underwater habitats generally depend on surface support systems because otherwise the structures would need to be much larger and more complicated in terms of maintenance and operations, explains Dale G. Anderson, P.E., who is retired but spent several decades overseeing the design and construction of various undersea habitats, including La Chalupa.

Designed by Koblick and engineers from submarine builder Perry Oceanographics of Riviera Beach, Florida, La Chalupa was initially used for undersea research in the waters off Puerto Rico at a design maximum depth of 150 ft. When research funding dried up, says Koblick, the habitat was moved to Florida, where it was stored in the Miami River for several years before being converted to the undersea lodge in 1986.

But even though it now welcomes non-professional divers and even features underwater pizza delivery for its guests, the habitat remains available for scientific pursuits. In fact, from March to June this year it hosted a hyperbaric medicine researcher/aquanaut who set a new world record by living underwater for 100 days without surfacing.

For Tony Webb, the managing director of Planet Ocean Underwater Hotels LLC, based in Key West, Florida, the dream is to construct a series of movable underwater habitats with multiple guest rooms. That is why Webb designed and patented a modular system that features a series of steel cylinders, typically 18 ft long and 12 ft in diameter, partially wrapped in large acrylic viewing panels and arranged horizontally off a central concourse.

A moon pool in the hotel — an opening that enables people to enter or leave the habitat without needing an airlock — would accommodate divers or even a miniature submarine, but most guests will arrive and depart through a 13 ft diameter elevator shaft that will connect the underwater rooms to the surface, where a covered walkway surrounds the elevator entrance.

At the surface, a support vessel will provide key services, including power generated by solar panels, wind turbines, and biofuel generators that can be fueled by the plastic trash created by the hotel. The support vessel will also be able to tow the movable hotel to a new location. At press time, the Planet Ocean project was establishing a Southeast Asia headquarters in Hong Kong to help develop operations in the Maldives, Malaysia, Thailand, and Indonesia.

Studying the seas

Roughly 5 mi south of Key Largo, submerged to a depth of 62 ft amid the coral reefs of the Florida Keys National Marine Sanctuary, is an underwater research facility that has welcomed scientists from universities and organizations around the world since 1986. Called the Aquarius Reef Base, it was originally constructed for the National Oceanic and Atmospheric Administration and stationed in the U.S. Virgin Islands but was relocated to the Florida Keys and is now owned by Florida International University.

More than 40 ft long and featuring a main pressure vessel 8 ft in diameter, Aquarius was designed by Perry Oceanographics according to standards for undersea pressure vessels set by the American Bureau of Shipping, says Anderson, who was responsible for the design, fabrication, testing, and certification of the Aquarius habitat in the mid-1980s while he served as program director of the University of Southern California’s national undersea research program, which funded Aquarius.

The tanklike structure features steel plates 0.75 in. thick supported by steel H-beams bent into a curve and welded to the inside of the hull. Spaced 24 in. apart, these steel ribs resist the external water pressure and reinforce the structure for internal pressure, Anderson says. The flanges of the H-beams support the interior fittings, such as plumbing, cabinets, and other items that are bolted to the habitat walls.

Aquarius is latched to a steel-framed base plate — covered in pipes for gas storage and other operations — that is anchored to the seafloor by four large piles. At the surface, a 33 ft diameter discus buoy provides power, life support, freshwater, communications, and other services to the underwater habitat through a 6 in. diameter umbilical hose.

Planning PROTEUS

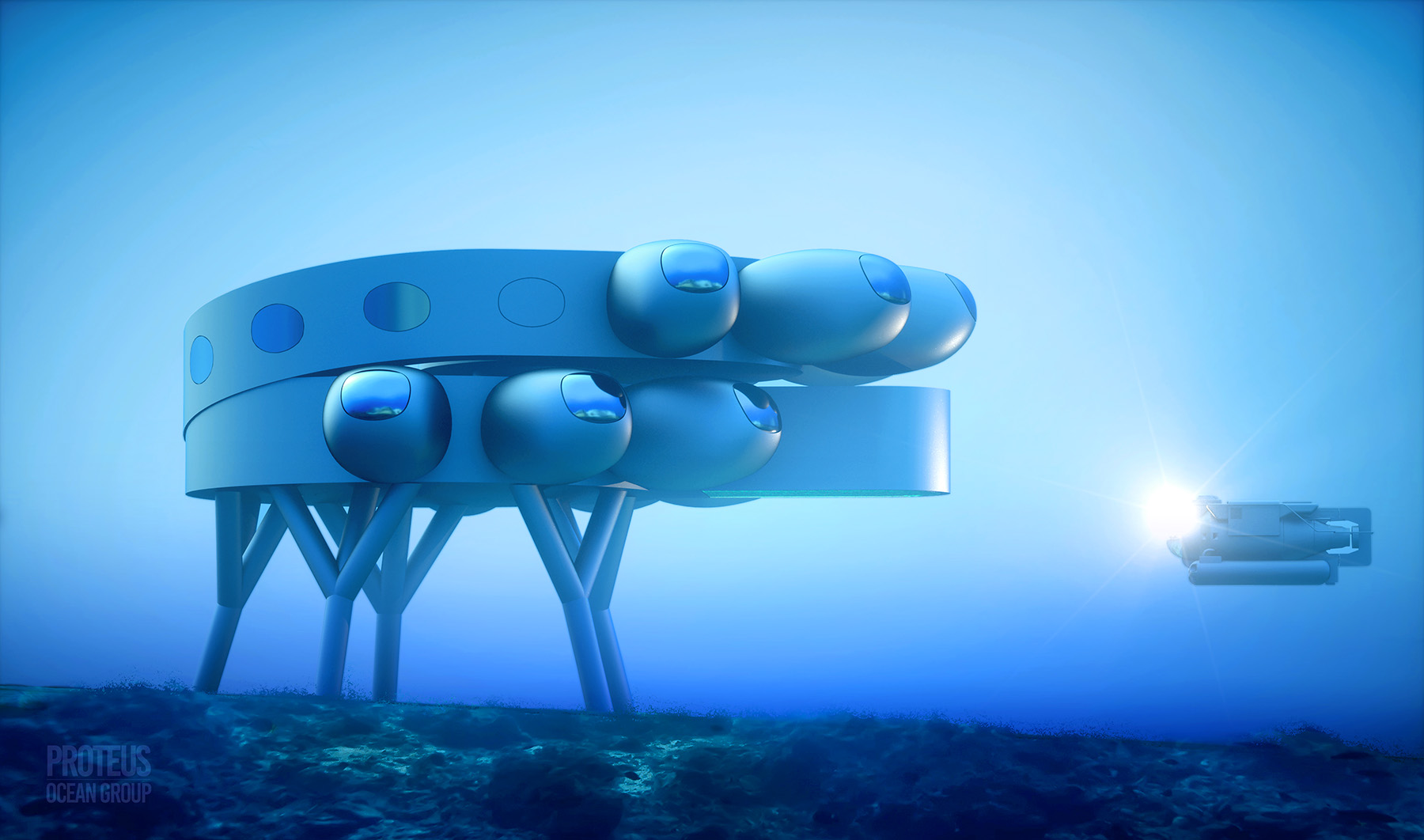

Aquarius has been used by NASA to train astronauts because the space agency considers the environment of the undersea habitat to be analogous to conditions on a space mission. But it is another underwater facility, still in the planning stages, that is being touted as an undersea version of the International Space Station. This is PROTEUS, a modular laboratory complex intended to be part of a connected network of similar submerged facilities.

PROTEUS is the dream of Fabien Cousteau, who founded the Proteus Ocean Group as a project of his Fabien Cousteau Ocean Learning Center, based in New York City. He is also the grandson of the famous French underwater explorer Jacques Cousteau, who helped pioneer underwater habitats with his Conshelf facilities in the 1960s. PROTEUS “will be a platform for global collaboration amongst the world’s leading researchers, academics, government agencies, and corporations to advance science to benefit the future of the planet,” according to a project press release.

As the world’s most advanced underwater research station, PROTEUS and the other installations in the network will share research and data on topics ranging from the protection of marine life and underwater exploration to food sustainability and the impacts of climate change, notes Randy Brandenburg, senior vice president of engineering at the Proteus Ocean Group. Eventually, some habitats in the network could also be used as underwater hotels to help more people learn about the ocean, Brandenburg adds.

And while PROTEUS will initially be dependent on umbilical connections for its power, life support, and other services, the goal is to eventually make such habitats completely self-sufficient. For example, the design of PROTEUS includes the world’s first underwater greenhouse, with aquaculture also expected to play an important role in providing food, Brandenburg notes. And wave motion could potentially help generate the habitat’s power.

Living undersea

Ironically, some of the people with the most experience designing underwater structures do not expect people to live beneath the waves for anything other than short periods. Underwater habitats are quite expensive to build and maintain and are susceptible to especially harsh weather at sea, notes Murphy. “It is my opinion that it is highly unlikely that undersea living will catch on as a viable way to live in the future,” Murphy says.

Likewise, Anderson stresses the challenges of living and working underwater — where at certain depths even oxygen becomes toxic, and humans must breathe special air mixtures and spend lengthy periods decompressing. The undersea world is like space: a hostile environment in which humans cannot stay without protection and support, Anderson says. Instead, he expects that remote underwater vehicles, operated by humans on the surface, represent a more viable and economical future for ocean exploration.

Still, the dream of living underwater has its proponents, especially given the possibilities presented by the blue economy. Two proposals in particular stand out.

Polish architect Krzysztof Kotala, the founder of 8+8 Concept Studio in Warsaw, Poland, has designed “underwater urbanized structures” that can help develop marine mining, ocean agriculture, undersea energy production, and other industries. These modular underwater structures would serve as bases from which people and machines could explore the undersea world and use those ocean resources.

Kotala has also proposed the Underwater Tennis Center, a sports complex that could feature tennis matches in facilities under acrylic domes.

The underwater urbanized structures include two main models: a fixed module and a mobile version. The fixed module has a hexagonal shape that can be attached to the seabed at a depth of up to 100 m. The mobile module would be diamond-shaped and designed to reach depths of as much as 300 m. Both types of modules would be covered in polygonal ceramic tiles to distribute the water pressure at different angles, dissipating the forces acting on the surface shell.

Kotala’s vision includes marine farms for fish, shellfish, and algae as well as greenhouse cultivation of algae, which would also generate oxygen as a byproduct. Ocean farming on an industrial scale in wild waters is the future of human nourishment, Kotala says.

Underwater mining would involve robots and other machines together with habitats and various facilities for the people who would keep these machines in operation.

Energy could be produced by nuclear power and by a series of large, flexible, perforated mats stretched over areas with strong ocean currents. The mats would capture the movement of water through impellers and convert that motion into electricity.

Ocean Spiral is a proposed underwater city from Shimizu Corp., one of Japan’s largest construction firms. Although conceptual, the design is intended for a deep ocean environment — an underwater plateau or continental rise at which the water depths could reach as much as 5,000 m.

The city would feature a 500 m diameter sphere known as the Blue Garden in which residents of the underwater city would live and an industrial facility called the Earth Factory that would sit on the seabed and be used to develop deep-sea resources. A spiraling tunnel structure known as the Infra Spiral would connect the Blue Garden to the Earth Factory. Trains inside the Infra Spiral would take people and critical supplies to the seabed factory and transport the factory’s products to the surface.

Resin concrete will potentially be the primary building material of the Ocean Spiral structures, and carbon fiber legs will anchor the city to the seabed. Although the top portion of the Blue Garden sphere will normally stay above water, protected by a floating breakwater structure, the entire sphere can be submerged to a safe distance under the waves in the event of extremely rough weather on the surface.

Are these schemes science fiction or the future of science and engineering? It’s hard to say. But according to the World Wildlife Fund, the blue economy is “conservatively estimated” to be worth $24 trillion. The value of these ocean resources will only increase over time, predicts Brandenburg.

So he expects that as science, research, and technology advance, the demand for human and robotic exploration and activities beneath the waves will also increase. “I can only see us spending more time undersea,” Brandenburg concludes.

Robert L. Reid is the senior editor and features manager of Civil Engineering.

This article first appeared in the September/October 2023 print issue of Civil Engineering as “Blue Future.”

Interested in learning more about how the future built environment might work? Register today for the ASCE 2023 Convention (Chicago, Oct. 18-21) and attend the exclusive early screening of ASCE’s next IMAX movie: Cities of the Future: Reimagining Our World.