By Robert L. Reid

The Elizabeth line is the first heavy rail system to pass beneath the British capital and the largest expansion of rail capacity there in 70 years. The project included 42 km of new tunnels and 10 new stations, excavated to depths of up to 40 m below grade.

The city of London is famous for moving people underground. Its subway system — officially the London Underground but affectionately dubbed the Tube — was the world’s first underground railroad when it opened in 1863. Its 11 lines can handle more than 1 billion passengers annually, according to Transport for London, which runs the day-to-day operations of the city’s public transport network.

In May 2022, Londoners welcomed the newest and perhaps most ambitious project the city had ever attempted in terms of subterranean mass transit: the Elizabeth line. Originally known as Crossrail, the line was renamed in 2016 in honor of the monarch at the time: Queen Elizabeth II.

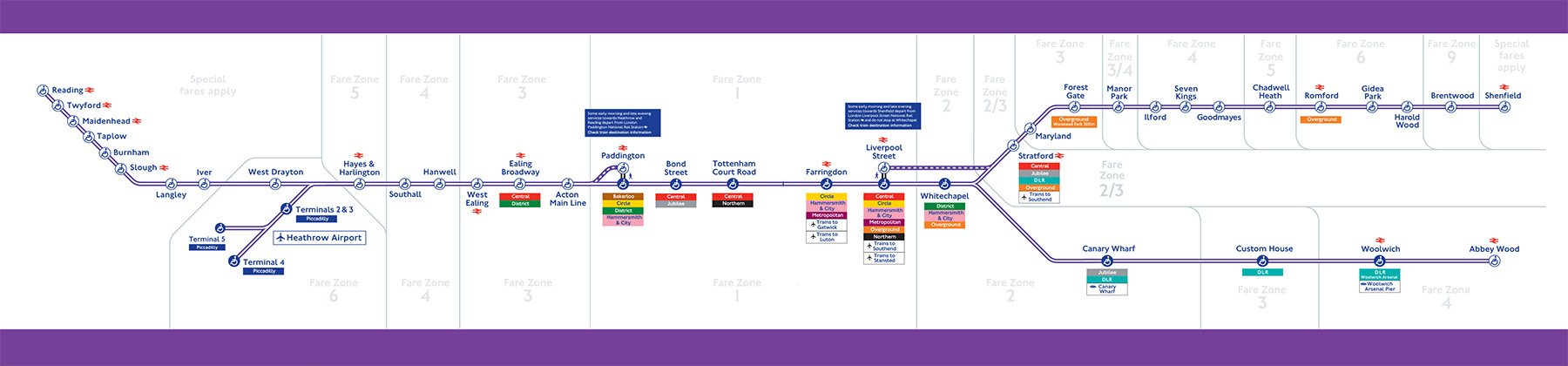

Considered the largest infrastructure project in Europe, the Elizabeth line covers a total distance of 100 km in an east-west alignment that features 31 existing rail stations and 10 new stations in central London, at Paddington, Bond Street, Tottenham Court Road, Farringdon, Liverpool Street, Whitechapel, Canary Wharf, Custom House, Woolwich, and Abbey Wood (see map on pages 62-63). All but the Custom House and Abbey Wood stations feature deep underground portions, with Liverpool Street the deepest station at 34 m below grade.

The new stations are linked via 42 km of new tunnels, consisting of twin bored-concrete structures over a 21 km long segment. The central section of the Elizabeth line includes various shafts and portals that house railway systems and mechanical equipment. Powered by a 25 kV overhead traction power system, the line also required the installation of more than 50 km of new track, the integration of three signaling systems, and upgrades to existing infrastructure, especially along the surface portions of the route outside London.

The Elizabeth line is part of the Transport for London network, although another organization, MTR Elizabeth line, manages and operates the trains and other parts of the new system. Constructed by Crossrail Ltd. — a wholly owned subsidiary of Transport for London that was established to build the new railway — the Elizabeth line connects to the existing Tube lines but is not itself part of the London Underground. Instead, it is a heavy rail system that uses trains 205 m long that can carry up to 1,500 passengers each.

“It is the first time heavy rail has ever gone underneath London,” says Alison Norrish, a director and fellow at Arup, which was extensively involved in the Elizabeth line project.

In a joint venture with AtkinsRéalis, Arup designed the tunnels for the entire project as well as several of the stations, underground and aboveground, including Woolwich, Tottenham Court Road, and Custom House, along with a maintenance depot. Separately, Arup also worked in integrated teams with Crossrail Ltd. and various contractors on other stations, such as Liverpool Street and Bond Street, and on other parts of the overall project, dating back to the 1990s and the original geotechnical investigations for the proposed route, Norrish says.

Deep dive

Excavated to depths of as much as 40 m, the Elizabeth line’s tunnels dive underground just before Paddington in the west and run deep beneath central London before bifurcating after Whitechapel. The underground segments then continue to the northeast, surfacing before Stratford Station and ending at Shenfield. To the southeast, the tunnels pass under the River Thames, and the line then surfaces after Woolwich and ends at Abbey Wood, Norrish says. Along this route, the tunnels cross under the Victoria, District, and Circle Tube lines, over the Jubilee and Piccadilly lines, and both under and over the Northern and Central lines, depending on location.

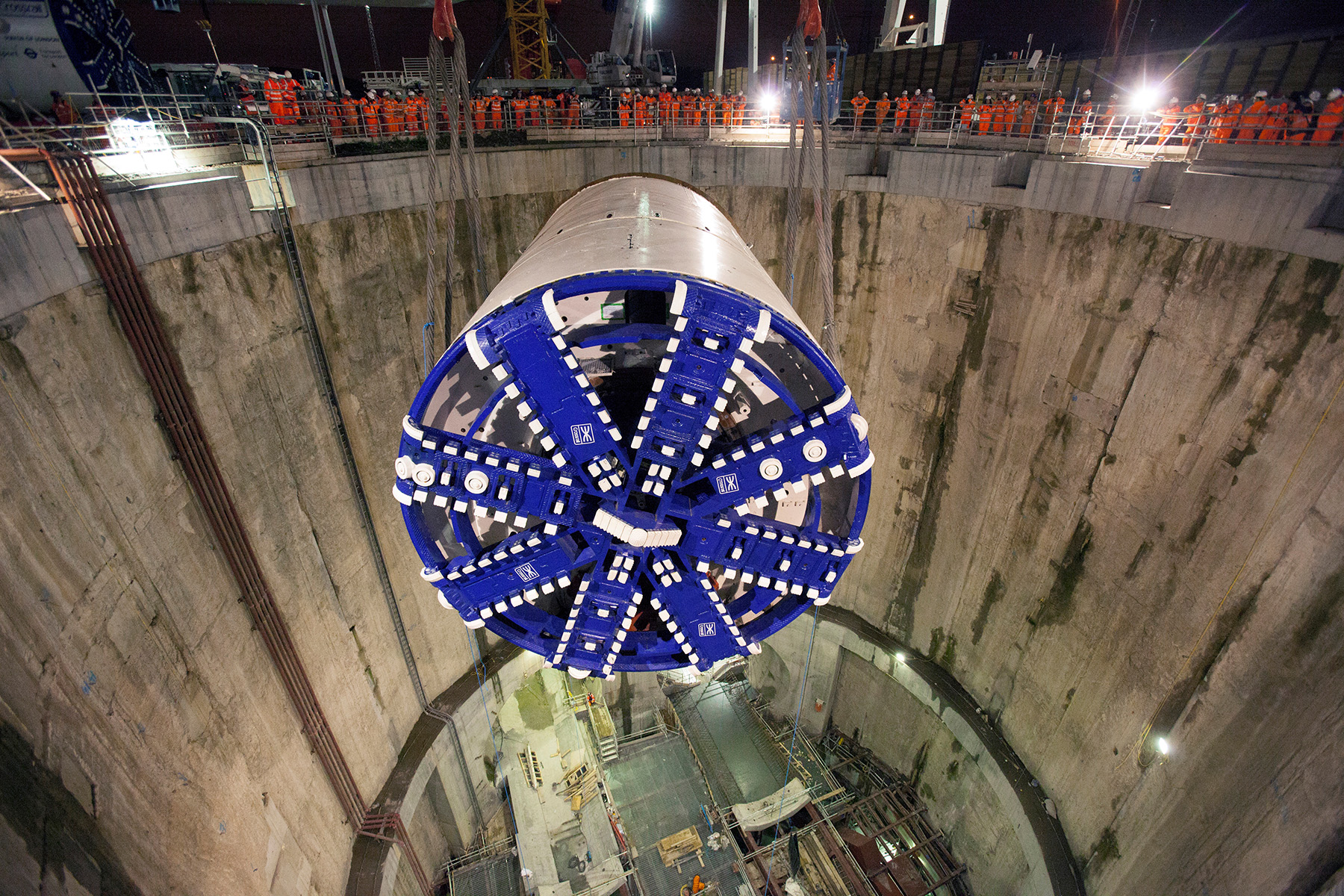

The tunnels were dug by eight tunnel boring machines — named Ada, Elizabeth, Ellie, Jessica, Mary, Phyllis, Sophia, and Victoria — that cut their way through geotechnical conditions that varied by location. Weighing 1,000 metric tons apiece, the TBMs plowed through the earth in four main drives from 2012 to 2015 that resulted in pairs of parallel tunnels, each with a 6.2 m internal diameter and a 6.8 m external diameter, says Norrish.

The soil conditions they encountered included river terrace deposits, London clay, the Lambeth Group (composed of gravels, sands, silts, and clays), Thanet Formation (sand), chalk, and other materials. Prior to the construction of the Elizabeth line, comprehensive ground investigations extracted soil and rock cores from more than 1,400 boreholes along the route; these boreholes reached depths of up to 70 m, according to the Crossrail website, www.crossrail.co.uk. Thousands of these cores are now stored in a natural, climate-controlled facility in the United Kingdom’s largest salt mine in Cheshire.

“These soil and rock cores played a crucial role in the Crossrail project as they allowed us to build up a detailed picture of the ground conditions below London,” said Mike Black, Crossrail’s head of geotechnics, according to the project’s website. “The information gained from them can be used by future London tunnelling projects.”

During its preconstruction phase, the project also involved one of the largest and most extensive archaeological investigations in the United Kingdom, according to the website. More than 100 archaeologists investigated 40 sites, finding artifacts that spanned “55 million years of London’s history and prehistory, dating from prehistoric, Roman and medieval eras and the recent industrial past,” the website noted. These artifacts ranged from mammoth bones to human skeletons found in mass burials that dated to the 14th century’s Black Death and other plagues.

Threading the needle

Because the basic locations for the new stations were already set, Arup’s tunnel designers “had to ‘thread the needle’ between the existing Tube lines and thousands of building foundations and utilities to find a route that could serve the station locations and not impact existing services, buildings, and operational infrastructure,” Norrish says. In fact, the ground beneath London is so crammed with other infrastructure that parts of the Elizabeth line are in almost unbelievably close proximity to other underground structures. Portions of the new Bond Street Station, for example, are just 30 cm from an existing Tube line tunnel.

To help manage the enormous number of potential underground obstructions, Arup relied on various tools and techniques, from software algorithms and risk-based analyses to public domain information and even direct observations of building heights, which can help predict the depths of their foundations, Norrish says.

For instance, many of the London buildings constructed before 1920 were simply built at grade or maybe with a basement, but nothing that extended too deep — perhaps just 3 m underground, Norrish notes. Starting around 1920, buildings constructed in London often featured piles, which went deeper as the buildings rose taller. Analyzing information about the height and age of the buildings, Arup’s engineers could determine what sort of piles they might encounter; this analysis could then be combined with information about the soil conditions to create a better picture of what obstacles might be met underground.

So instead of having to consider potentially 20,000 buildings that might present a subterranean challenge, “actually there were only about 80 that could (have been) a problem, and we then focused our attention on those,” Norrish explains. Arup also undertook extensive settlement analyses and damage assessments to evaluate potential ground movement in response to the tunneling and station excavations.

Mitigating ground movement

To mitigate the risk of ground movement and possible damage to buildings at the surface during tunneling, the project relied on more than 75,000 sensors to collect critical data, according to the Crossrail website. These included robotic theodolites (which measure angles) that gathered data from prisms attached to buildings along the route; hydraulic leveling cells that detected small changes in water level; hand-held theodolites to manually monitor movement at the surface and extensometers that measured movement belowground; and additional theodolites that generated data from prisms attached to the walls of newly excavated tunnels.

“This wealth of data created a comprehensive picture of the impact of works and ensured the team could respond where necessary to protect the buildings aboveground from damage,” explained the Crossrail website.

In areas of shallow excavations or where multiple tunnels, cross passages, and other passages had to coexist, the potential for cumulative ground movement effects was significant, the website noted. In these locations, the ground was stabilized by a method known as compensation grouting.

As the website explained: “Engineers created a number of vertical shafts several meters deep. From the shaft walls, small horizontal pipes were installed into the earth radiating from the shaft. A cement-like substance known as grout is injected into the pipes, reaching deep into the ground. This process lifts the ground in specific locations and helps to reduce any differential settlement that may have occurred at the surface. Once the tunnelling is complete, the shaft is backfilled and the ground reinstated.”

Compensation grouting was used at Bond Street, Tottenham Court Road, Farringdon, Liverpool Street, and Whitechapel.

Because the line’s heavy trains can transmit noise and vibration through the soil and piled foundations to the buildings above the tunnels — which can cause considerable problems for recording studios, medical facilities, and other enterprises at the surface — workers installed floating track slabs in key locations, Norrish says. These systems featured heavyweight concrete slabs supported on elastomeric rubber bearings and springs “to absorb the vibrations of the heavy trains at the source.” More than 3 km of floating track slabs were used along the route.

At the Canary Wharf station, in the Docklands region near London City Airport, the facility sits both underground and underwater: The station is 18 m below the surface of the water in the West India Quay dock and then another 10 m into the ground. Because the station had to be constructed in the water, workers installed a perimeter sheet pile wall completely around the dock. The site was then dewatered and excavated and the station constructed, says Norrish. The worksite’s proximity to noise-sensitive offices for major law firms and banks, among other critical tenants, meant that a special “silent” method was used to install several hundred of the roughly 1,000 piles used to support the structure.

The system used hydraulic pistons to push piles down into the ground, instead of pounding them down with hammers with all the accompanying noise and vibration, says Norrish. The same process was used at other noise-sensitive locations on the project and at sites where there was insufficient room for the traditional cranes and hammers.

Spraying spaces

While the running tunnels along the Elizabeth line were excavated by TBMs and constructed from segmental concrete linings, many station platforms and adjacent crossovers for trains to switch tracks were constructed using sequential excavation and a technique called sprayed concrete lining, which “created the Elizabeth line’s vast caverns, measuring up to 17 m high and 16.5 m wide — the largest underground spaces in London,” according to the website of Mott MacDonald, which served as the project’s SCL consultant, among other design and engineering tasks.

Five of the line’s new stations — Bond Street, Tottenham Court Road, Farringdon, Liverpool Street, and Whitechapel — were constructed using SCL. The technique was also used to create the enormous caverns for a junction near the Stepney Green Tube station that enables trains to connect to the northeastern and southeastern routes. The process creates “a smooth, curved profile, enabling the sprayed concrete lining to act in compression like an eggshell, supporting the surrounding ground. When the SCL tunnel is fully excavated, waterproofing and a secondary concrete lining are installed,” according to Mott MacDonald.

Using and reusing

The Connaught tunnel — a disused Victorian-era rail structure in the Docklands area — is the only existing tunnel to be reused as part of the Elizabeth line. The 550 m long, brick-lined tunnel was built in 1878 but had not been in passenger use since 2006. Because the original structure was too small to accommodate the Elizabeth line trains, the tunnel was deepened, strengthened, and widened, according to the Crossrail website. In addition, “135 years of coal and soot from the steam trains that originally used the tracks” was removed, the website noted.

To create a dry work environment for the tunnel rehabilitation, workers built a large cofferdam to drain 13 million L of water from the docks above the structure, the website explained. Draining and refilling the docks took three months.

Another historic tunnel — the Kingsway tram tunnel in the London boroughs of Camden and the City of Westminster — was also used during the construction of the Elizabeth line, but only in a temporary role. Originally constructed in 1906, the historically protected tunnel closed in 1952. Crossrail Ltd. took over the Camden section of the tunnel in 2012 because it sat directly above the route of the Elizabeth line tunnels through Holborn, according to the Crossrail website.

During construction of the Elizabeth line, an 8 m deep, 5 m wide shaft was excavated inside the tram tunnel “to allow engineers to pump ... grout into the ground to correct tiny ground movements that occurred as a 30 m deep temporary access shaft was built nearby,” and two of the project’s TBMs cut through the ground below the tram tunnel. The site was also used “to pump cement, water, air, and electricity to the new railway being built 6 stories below ground,” according to the website.

The Kingsway tram tunnel is being restored, and all “visible evidence of its use to support construction of the Elizabeth line” will be removed, the website noted.

Subterranean scale

Designed to accommodate some 200 million passenger journeys each year, the Elizabeth line is expected to increase central London’s rail capacity by 10% — the largest increase in the city’s transport capacity in more than 70 years, according to the Crossrail website.

But because so much of the project was constructed underground, few people really appreciate the size or complexity of the work, notes Norrish. “People thought in terms of the Tube, whose tunnels are 4.5 m in diameter,” she notes. But the running tunnels of the Elizabeth line are more than 6 m in diameter, and the platform tunnels are nearly 11 m in diameter, which is “enormous!”

Moreover, the work was often done from small entrance spaces at the surface — a process that Norrish compares to “keyhole surgery,” the medical procedure that relies on a tiny incision to access the part of the body the surgeon will operate on.

At Liverpool Street, for example, the platform tunnels, concourses, elevators, and other features were all constructed from an entrance dug within a public garden, while at Whitechapel, “we took over just half of a car park” to launch the tunneling and other underground work, Norrish says. Meanwhile, above and around these massive subterranean efforts, “people were going about their lives with no idea of the scale of what was going on underneath their feet.”

For more information

The Elizabeth line was an extensive, multifaceted project, of which this article discusses only certain highlights. The engineers, architects, contractors, specialty consultants, and others involved in the decadeslong effort are too numerous for a traditional project credits list. Instead, those interested in learning more about how a modern heavy rail system was designed and constructed beneath one of the world’s busiest cities can visit www.crossrail.co.uk and also https://learninglegacy.crossrail.co.uk, which is described as a “collation and dissemination of good practice, lessons learned and innovation” during the Elizabeth line effort.

Although these websites are no longer being updated, the existing content features detailed discussions of the massive undertakings that went into the Elizabeth line, as well as technical papers, journal articles, videos, and other material on topics ranging from engineering and innovation to program management, health and safety, and various other information of interest.

Robert L. Reid is the senior editor and features manager of Civil Engineering.

This article first appeared in the September/October 2024 issue of Civil Engineering as “Heavy Rail Beneath London.”