By Leslie Nemo

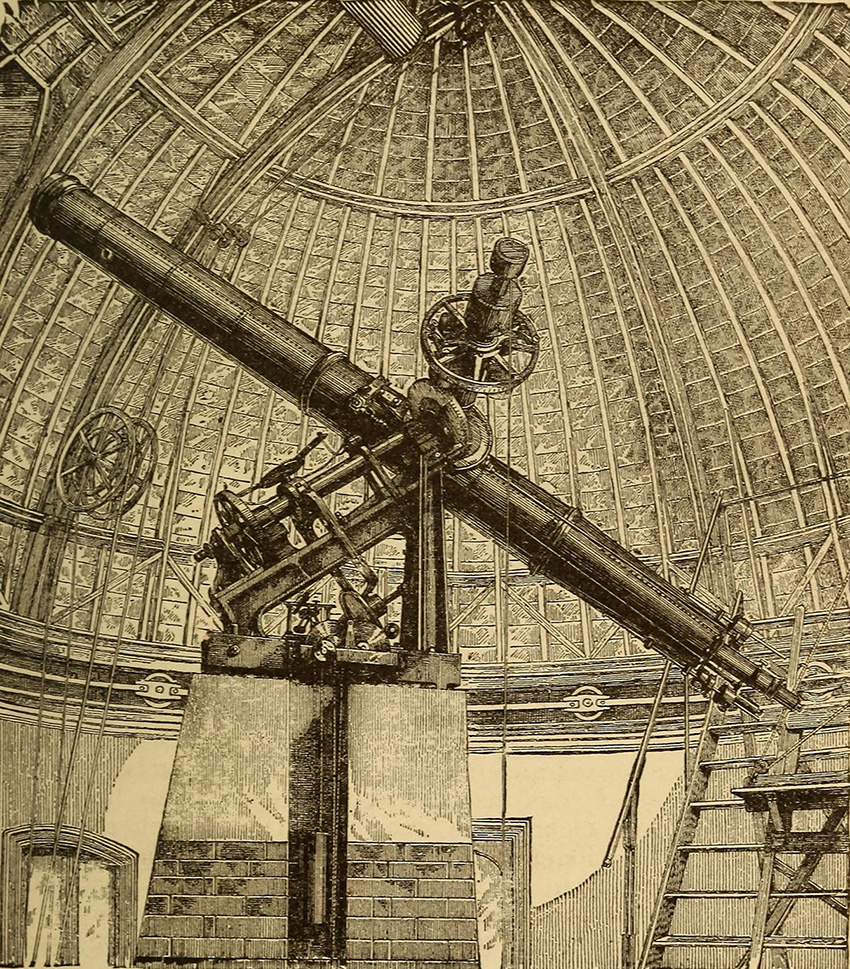

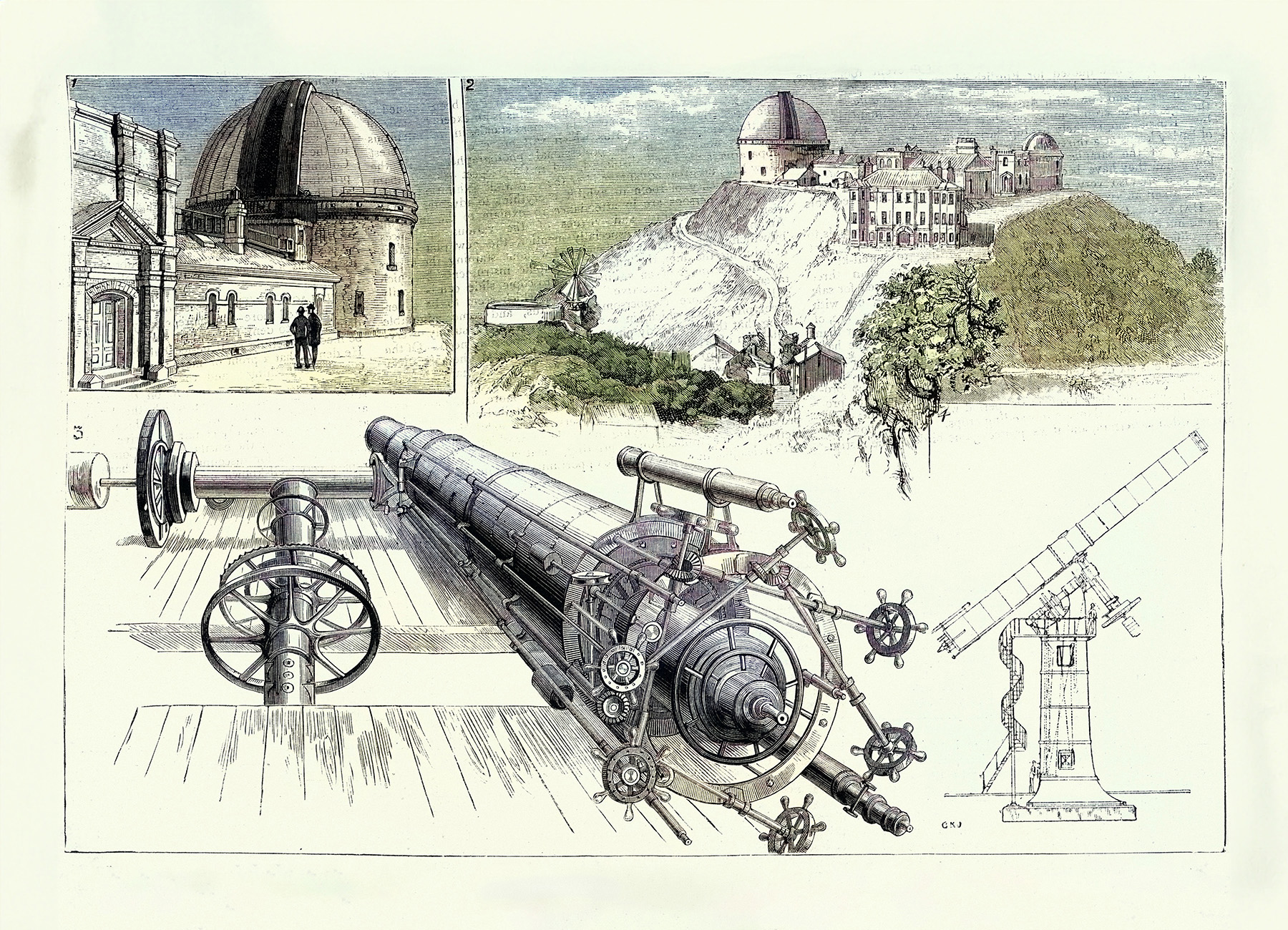

The main refracting telescope inside the Lick Observatory was the largest of its kind when it came together in 1888. Its 36 in. wide glass lenses, which collected and focused light, performed their task from atop Mount Hamilton outside San Jose, California. The facility was the first in the world to take advantage of the clearer air found on a mountaintop.

Dozens of scientists and engineers, some with more formal training than others, collaborated for more than a decade to build a project of unprecedented size and altitude, which included the transportation and water infrastructure that a small observatory community would need to make use of the telescope and other scientific gear on-site. Together, the team created a product so successful that it set a new standard for the sites of future observatories. And lest there be any confusion about how the observatory was made possible, the casket of James Lick, the project’s benefactor, lies in the large telescope’s foundation.

Lick was an unusual millionaire. Having made the bulk of his fortune through buying San Francisco land at the cusp of the Gold Rush, he wanted to leave a physical mark on California when he died. Lick considered oversized statues of himself and his parents and even a pyramid that would consume an entire city block.

But by the time he gifted property to the California Academy of Sciences in 1873, he had decided on a telescope, an idea that he shared with George Davidson, the president of the Academy, when he visited Lick’s office to thank him for the gift.

Davidson’s own work showing the value of observing the heavens from high elevations, along with input from other experts, helped persuade Lick to build the observatory to house the telescope in the mountains. The higher a land-based observatory, the less atmosphere there is to intercept the light coming from space, and the less disruption to the image quality.

Lick created the Lick Trust on July 16, 1874. The trustees were given $700,000 to install “a powerful telescope, superior to and more powerful than any telescope ever yet made,” according to the trust document found in Publications of the Lick Observatory of the University of California (Vol. 1) by Edward S. Holden.

By March 1875, however, Lick was frustrated by the trust’s lack of progress. He dissolved it, only to form a new one immediately after, this time helmed by Capt. Richard S. Floyd. The former Confederate soldier had moved to California after the Civil War and had worked a handful of jobs before being introduced to Lick in 1874. Lick had been impressed with Floyd, and to the younger man’s surprise, Lick named Floyd president of the second trust even though he did not have a background in astronomy or engineering.

That same summer, Lick and the new trust decided on Mount Hamilton as the best fit for the observatory, as its 4,265 ft peak was rarely obscured by the nightly fog that covered the valley. Lick proposed to Santa Clara County that it build a road to the peak, and he offered initial funding to be repaid with bonds. The county agreed, and the Herrmann Brothers began surveying the mountain for a feasible path to the top.

Charles Herrmann, who was serving as the Santa Clara County surveyor at the time, and his brother A.T. opened their firm after the former trained as a civil engineer in Germany and immigrated to the United States. A.T. eventually became the overseeing engineer for the project, drafting specifications and drawings after the grade stakes were set for each section. The road grade could never exceed 6.5% because of the mules and horses pulling heavy loads.

In February 1876, the trust chose E.L. Derby as the contractor to build the road. By May, Derby had been paid just over $45,000 when suspicions about the work quality led to an investigation by the county board of supervisors and the forfeiting of Derby’s contract. The rest of the route was completed by Drinkwater and Swall, who also leveled the existing road begun by Derby, replaced or strengthened box culverts, and reworked riprap above the creek, according to a letter written by the replacement contractors to the Santa Clara County Board of Supervisors that ran in the San Jose Daily Herald in January 1877.

On Jan. 9, 1877, the trust and county teamed up to inspect the road and declare it finished. The cost was $73,458.88. According to the same article in the Herald, the project used 237 kegs of blasting powder and 55 lbs of Giant powder, the latter of which is likely a reference to the explosives manufacturer the Giant Powder Co. in the San Francisco Bay Area.

News reports in the San Jose Weekly Mercury detailed how workers encountered hard rock six or seven times and that “a well-tempered drill will cut from two to four inches in one sharpening.”

While crews worked diligently to finish road construction, there was trouble behind the scenes. In September 1876, Lick dissolved the trust once more, only to re-form it again, with only Floyd kept among the new batch of men. However, that would be the last time the trust was dissolved, as the millionaire died less than four weeks later, on October 1.

Soon after, lawsuits from Lick’s relatives and disputes about how they would be paid their legacies created a yearslong delay in observatory progress, as the trust waited to see how the cases would be resolved.

As stated earlier, Lick’s deed called for a large and powerful telescope. Ultimately, the group opted for a 36 in. refractor telescope — a model in which the glass lenses at the end of the telescope would stretch 3 ft across.

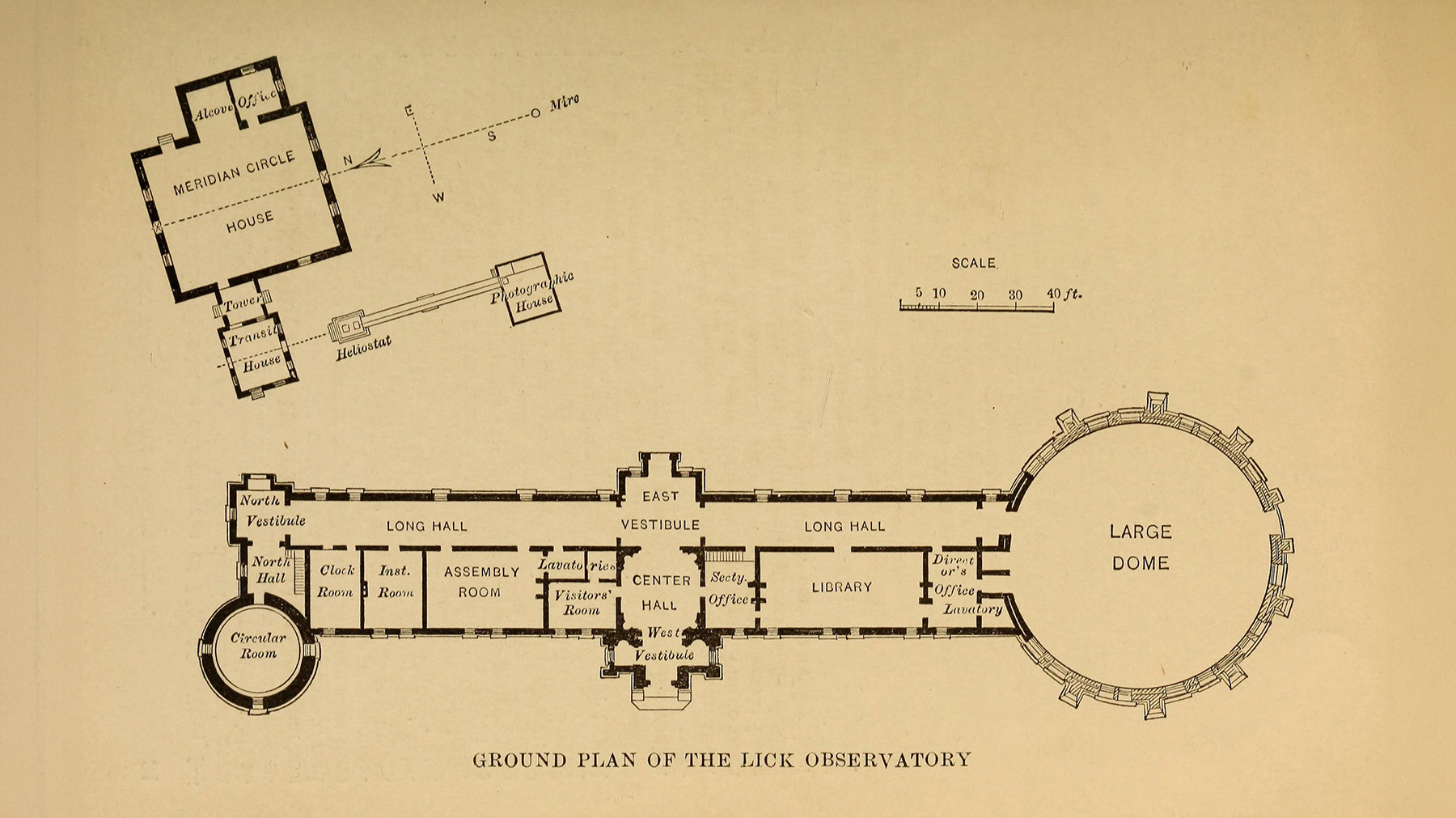

Accompanying the “Great Refractor,” as it was sometimes called, would be a 12 in. telescope, domes to house each telescope, an array of auxiliary buildings for other scientific instruments, a library, a photographic laboratory, research facilities, offices, housing, and a kitchen, to round out the main building, as well as a pumped water system fed by a nearby spring.

On July 23, 1880, a small crew reached the summit of Mount Hamilton to begin construction of the observatory, starting with worker housing. The group was under the direction of Thomas Fraser. Originally a ship cabinetmaker in Nova Scotia, Fraser was the foreman at Lick’s estate in Santa Clara after moving to the U.S. Fraser had introduced Lick to Floyd, and as the observatory plans developed, he was appointed superintendent of construction.

In August, 12 men began building the road to a spring Fraser had identified on an 1878 trip to the site. The spring was about 0.9 mi away from the summit of Mount Hamilton, according to a letter from Fraser to the aforementioned Holden, an astronomer and the future director of the observatory.

The road took seven weeks to build, as it required blasting through rock for most of the distance. Workers also graded the land for a boiler house in which a 20 horsepower boiler would provide steam power to a pump. This pump connected to wooden water tanks with a combined 10,000 gal. capacity via a 3 in. diameter pipeline. From there, a 2 in. iron pipeline carried water to the observatory site.

That same summer in 1880, Fraser and his team blasted on Mount Hamilton’s peak so that all buildings and piers could rest on solid rock. The crew used 1,050 lbs of black powder and 595 lbs of strong explosives, namely Giant and Thunder powders, along with 4,400 ft of fuse.

Site leveling was completed the following summer, in 1881, when more than 40,000 tons of rock were removed. The explosives, drills, and up to two dozen workers chipped away at the mountain together.

Also that year, the structure housing the 12 in. telescope and its small dome was completed. For the 29.5 ft diameter foundation, workers dug and blasted through 3.5 ft of rock before using pickaxes to delve another foot into the rock to level the surface. Per the Fraser letter, a “boat” of Portland cement was placed on the foundation. The walls required 150 barrels of cement, 60 barrels of lime, and 140,000 bricks, according to Fraser. All bricks were made on-site: Fraser had come across a patch of clay beds about a mile from the summit, from which a contractor turned out more than 3 million bricks — 10,000 a day, according to historical collections from the Lick Observatory.

The smaller telescope required a 13.5 ft diameter circular support pier. Workers installed a capstone to hold the mounting on top of the pier, which was held in place with cement and “a long iron bolt that goes clear through the stone to the bottom (of the) arch in the vault below,” according to Fraser. Fraser and his crew also built the dome enclosing the telescope by steam-treating wooden beams and bending them into place with the help of anchors. A layer of plated-copper sheeting made up the rest of the structure, save a sheet of corrugated steel to cover the 3 ft wide opening needed to see the sky, according to Eye on the Sky: Lick Observatory’s First Century by Donald E.E. Osterbrock, John R. Gustafson, and Shiloh Unruh.

By 1885, almost every part of the main building was complete. The glaring exceptions were the main telescope and its dome. The size of the dome could not be calculated until the engineers knew how long the telescope would be, which in turn depended on the focal length of the 36 in. lenses (or how far away from the glass an astronomer needed to be for a clear picture). The distance had to be calculated from the two glass pieces themselves. Charles Feil, a glassmaker in Paris, earned the production contract, but attempts to create the second lens, in particular, repeatedly ended in broken failures. After 18 attempts, including a version that cracked in transit, a complete second lens was shipped to the U.S. in 1886.

After receiving both lenses, Alvan Clark and Sons, a Massachusetts-based telescope production firm, removed about 100 lbs of glass as part of the polishing and shaping process. The disks were completed in the fall of 1886 and made the trip to California via private rail car. The lenses traveled up the mountain via wagon, and once at the summit, they were stored in a safe until installation.

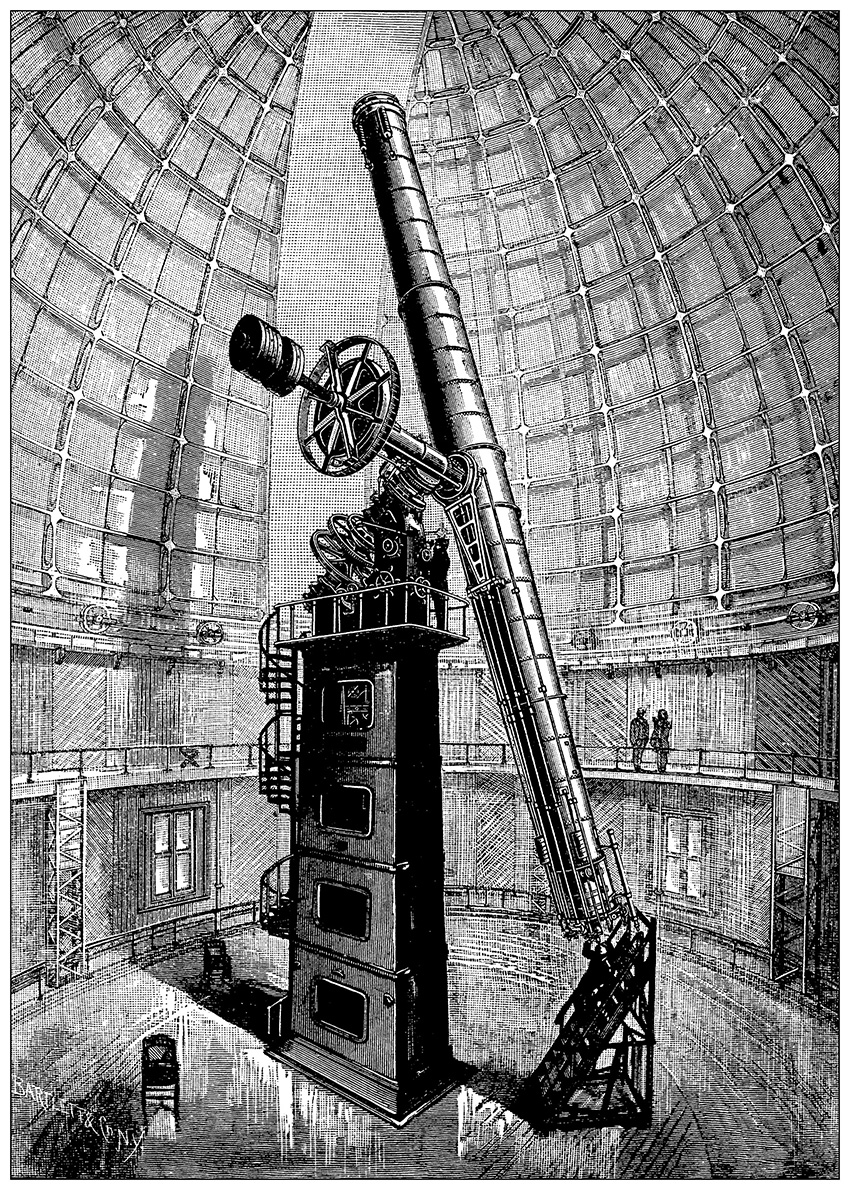

The Clarks estimated that the focal length of the lenses would be about 55 ft, and with this measurement in hand, dome construction could begin. The contract for the large dome was awarded to Union Iron Works of San Francisco, a firm that built the first steel steamship on the Pacific Coast, which launched in 1885. The company agreed to build the structure for $56,850, about half the cost of other bids.

The final design called for a dome with a 75 ft, 4 in. outside diameter. Per a specifications document signed by a Union Iron Works representative, the dome had two main girders that crossed it 10 ft apart. These girders were “26 inches in depth and to be of steel plate and angles; the web or plates to be (0.25 in.) in thickness in convenient lengths for transportation.”

Another 18 girders, nine on each half of the dome, “will be 26 inches in depth, the web formed of 3/16 inch steel plate.”

Openings in the main girders created space for four double shutters. The entire frame was assembled with service bolts and stop rivets — first on-site at the Iron Works for an observatory representative to inspect, and then marked with assembly instructions before dismantling for shipping.

The dome covering comprised galvanized steel plates double-riveted into place and hammered into the correct shape with a cast-iron die that provided the correct concavity of the dome.

To create the rotation needed so that the telescope could follow the stars in the sky, the design called for the base ring of the dome to be bracketed in 22 places to pairs of wheels called “guide rollers.” Each pair of guide rollers in turn connected to a carriage holding three more wheels, which rolled on a base plate made of 44 sections of cast iron that bolted into the granite of the dome in 176 places.

The dome’s hydraulic floor, which had a 60.5 ft diameter, also had to move up or down about 17 ft to help astronomers reach the eyepiece of the telescope no matter how it was angled. The hardwood floor rested on 24 girders “radiating from a central plate ring,” according to contract documents.

To turn, a continuous wire rope around the base of the dome connected to a driving pulley in the basement and hand-operated equipment on the moving floor. The total weight of all dome segments was 243,837 lbs.

Eventually, all the dome materials made it to the summit. Soon after, another firm began to assemble the telescope itself. The Cleveland-based partnership of Worcester P. Warner and Ambrose Swasey primarily made machine tools, but it also dabbled in telescopes. The pair first had a contract to make the 12 in. telescope before being commissioned in spring 1886 for the 36 in. model.

Warner and Swasey made the 58 ft long primary telescope tube from rolled Pittsburgh plate steel, but a completely uniform design was prone to bending — gravity alone can flex telescopes enough that the lenses misalign. Instead, Warner and Swasey calculated that the tube needed to be 4 ft diameter at the center and taper at both ends. The firm had a hard time finding high-quality carbon steel, so other parts of the design were a struggle to cast, such as the four-sided cast-iron pier that was 10 ft by 17 ft at the base and tapered to 4 ft by 8 ft at the top, according to the National Park Service’s webpage, “Astronomy and Astrophysics: Lick Observatory Building.” Another feature difficult to cast was one of the mounting tubes, dubbed the polar axis, between the base and the main telescope tube.

Before any of the iron for the telescope made it to the mountain, the trust committed to a desire Lick expressed at the end of his life. On Jan. 11, 1887, Lick’s casket was placed into a brick-and-stone vault built to support the 36 in. telescope pier. Months later in November, freight cars from the Midwest arrived with the Warner and Swasey steel. From the San Jose train station, teams of six to eight horses took segments, some of which weighed several tons, up the mountain. It sometimes took two days for a single wagonload to be delivered. By December 12, all the pieces had arrived.

Floyd, who was overseeing the mounting of each segment, made the rigging that hoisted components into place five times stronger than he thought necessary as a precaution against any segment falling and breaking through the floor below. Each segment of the hollow iron pier rested on bolts, which in turn sat on the masonry support system.

With the glass removed from storage and placed into the skyward end of the telescope, the team — which included Floyd, Swasey, Clark, and a few others — gathered on the mountain, but they had to wait for a brutal storm of wind and rain to pass before getting a chance to see what the telescope could do.

The first attempt, on Jan. 3, 1888, came with the realization that the focal length had been miscalculated by 6 in. Days went by as the glass was removed and Swasey sawed 6 in. off the end of his design. The team got its first real look at a planet — Saturn — four days later, on January 7. However, Fraser missed the momentous day because he had to leave to start a new job.

On June 1, 1888, the trust met with regents from the University of California to officially transfer the deed for the observatory and the adjacent property to the university. Floyd died just over two years later, at the age of 47, while Fraser died a year after that, at the age of 49.

The Great Refractor telescope has had a long life atop Mount Hamilton. Astronomers turned to the telescope to make an atlas of the moon, show details of how various bodies in the Milky Way are arranged, and more. Though it has been officially retired from research, the giant telescope still stands as a testament to what amateurs can build — with some advice from trained professionals, of course.

Leslie Nemo is a journalist based in Brooklyn, New York, who writes about science, culture, and the environment.

This article first appeared in the November/December 2024 issue of Civil Engineering as “Telescopes at New Heights.”