By Matthias Peltz, P.E., and Michael Stein, P.E., M.ASCE

The Port Lands Flood Protection and Enabling Infrastructure project is reshaping downtown Toronto with a comprehensive master plan that includes resilient flood protection measures, urban renewal initiatives, and a network of four new innovative bridges. It is part of the computer-aided design, $1.3 billion project set to be completed this year. The plan will revitalize the Toronto Port Lands, an industrial and recreational waterfront neighborhood, by excavating two new outlets and a new mouth for the existing Don River, cleaning polluted land, designing habitat-rich wetlands, building new transit infrastructure, and creating 25 hectares of publicly accessible green space and parkland. The PLFPEI project will provide crucial flood protection against extreme weather events while increasing harmony between urban life and natural habitat preservation.

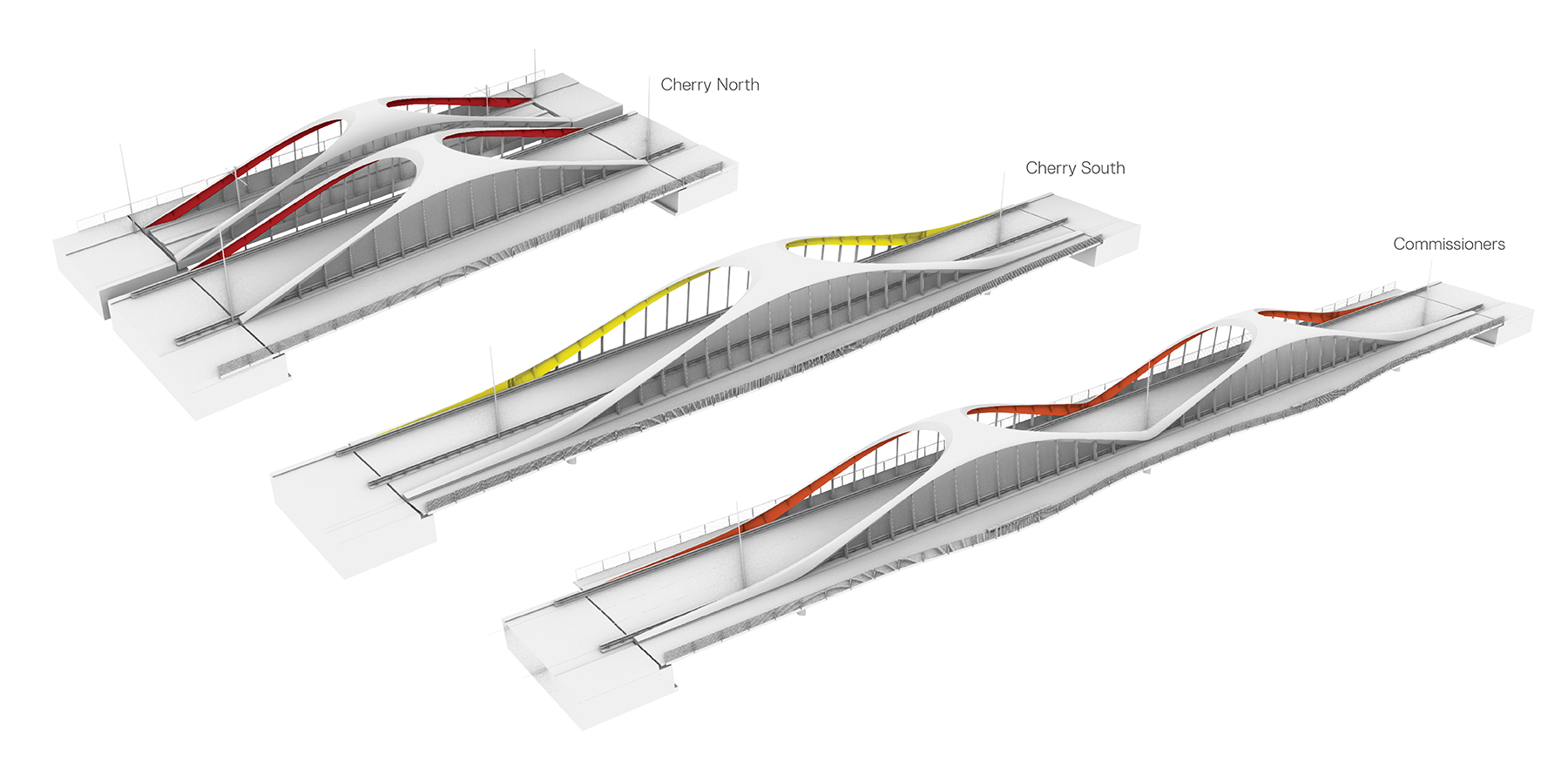

To enhance accessibility between downtown Toronto and its reinvigorated waterfront, the PLFPEI project commissioned four signature bridges facilitating three critical waterway crossings. Aiming for a symbolic representation of the city’s innovation, the bridges serve as vital conduits for light rail, vehicular, bicycle, and pedestrian traffic. Three of the new crossings span the Cherry Street area: the Cherry Street North and the light-rail transit system bridges and their counterpart, Cherry Street South, offer panoramic views over the newly naturalized Don River mouth and connect seamlessly to the southern Port Lands. Meanwhile, the Commissioners Street Bridge, spanning approximately 150 meters, transverses the naturalized riverbed and wetlands to link the eastern expanse of the Port Lands.

Further reading:

- Toronto waterfront project features naturalized river channel

- Seattle waterfront project restores beach habitat

- How engineers saved Washington, DC’s, iconic Arlington Memorial Bridge

The design team worked closely with Waterfront Toronto, a public organization spearheading the PLFPEI project, to ensure that the bridge designs aligned with the goals of the master plan. The team included schlaich bergermann partner’s New York City office in collaboration with the local Toronto office of engineering firm and prime consultant Entuitive and the New York City office of Grimshaw Architects. Based on the experience gained with novel bridge designs using curved steel plates, sbp – together with the rest of the design team – developed the highly efficient form of the design. Entuitive further led the project through the construction phase. Specialized steel contractors were involved in early discussions during the design process to ensure the feasibility of the structure with its complex steel geometry.

Future bridges

The design team was tasked to create “bridges to the future” that embodied Toronto’s leadership in design and manufacturing. Embracing the project’s ambition, sbp crafted a double-curved shell structure that reimagined common tied-arch bridges. The innovative approach to use the principle of a tied arch, where the arch is made from double-curved steel plates, not only maximized material efficiency and reduced costs but also addressed key challenges such as foundation limitations due to challenging soil conditions. With critical constraints for traffic clearances for pedestrians, vehicles, and rail, the design process prioritized the seamless integration of smooth curvature and structural integrity through the use of advanced computational tools such as Grasshopper, from Seattle-based Robert McNeel & Associates, and SOFiSTiK, from SOFiSTiK AG of Nuremberg, Germany.

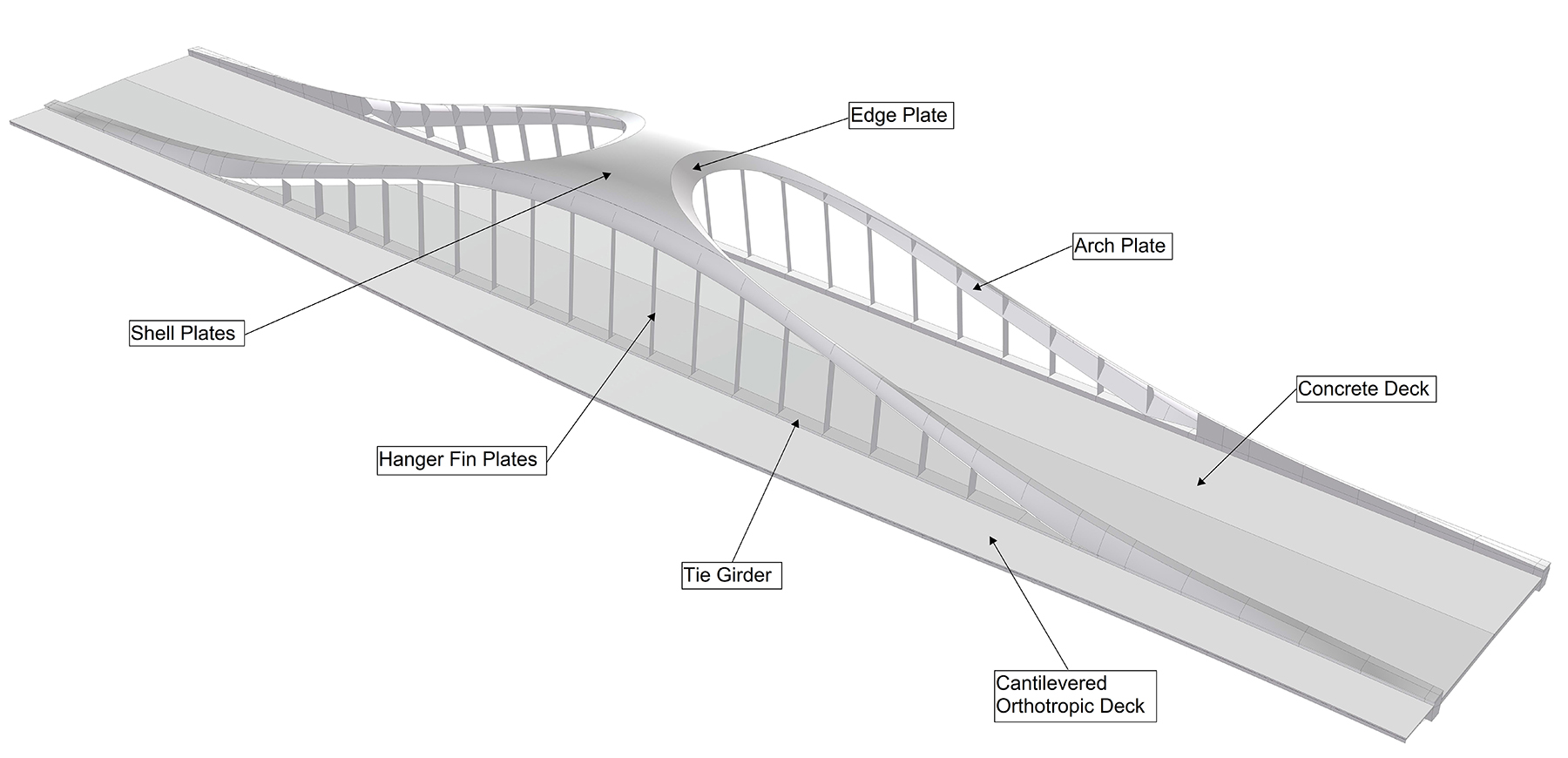

The hybrid shell-arch concept relies on cross beams to support the deck crafted from welded I-beams that were designed to span between the main girders. Notably, these cross beams feature a top flange that mirrors the cross slope of the bridge deck, ensuring stability and uniformity in load distribution. The steel shell is the backbone of the bridge, consisting of shell, arch, and edge plates that collectively form the primary load-bearing structure. This system is engineered to carry loads in compression only, adhering to the traditional principles of a tied arch. By evenly dispersing compression forces across the entire shell, the bridge employs relatively slender steel plates with a maximum thickness of 80 millimeters.

To provide lateral stability for wind and seismic loads, the design team used hangers formed from fin plates that efficiently transfer these lateral loads from the steel shell to the cross girders and subsequently to the supports below. The roof structure provided further stability by connecting the opposite sides of the shell. Local and global buckling of the shell was addressed by fully welding the fin plates to the girders and to the steel shell with steel plate thicknesses derived from nonlinear buckling analysis.

Site situations

The family of four bridges, while unified by shared design principles, were meticulously tailored to suit individual site conditions and functional needs. While adhering to a cohesive design ethos, each bridge in the family underwent bespoke adaptations to accommodate diverse site conditions and functional requirements. Variances in width and pier locations were calibrated to optimize structural efficiency. This led to the Cherry Street North bridges crossing the channel with a single span each, while the Cherry Street South and Commissioners Street bridges feature multiple piers for continuous beam action, thereby mitigating structural demands in the deck girders. The self-anchored design obviated the need for extensive horizontal support forces, streamlining construction and enhancing overall project feasibility.

Contaminated soil in the industrialized Port Lands created challenging site conditions for the foundation design. As a result, the structural system was chosen primarily to maximize the vertical reaction forces and minimize lateral reaction forces and reduce any foundation works. At the same time, the location and circumstances of the site also provided unique opportunities. The site location at Lake Ontario allowed the design team to conduct most of the bridge construction off-site with the final delivery of the bridges completed by barge. The bridges were prefabricated and painted in the manufacturer’s shop with minimal site work and under conditions that made it possible to fabricate a fully welded steel bridge within the required tolerances.

Fabrication challenges

The double curvature of the steel shells posed a unique fabrication challenge, requiring the use of innovative shipbuilding manufacturing processes. Central Industry Group, a Netherlands-based specialist in crafting complex 3D-formed steel sheets, was enlisted to manufacture all double-curved plates. The design team furnished CIG with a digital model of the bridges, detailing the precise curvature and geometry of the steel plates. Given the complexity of the double curvature, automation wasn’t a viable option. Instead, the project relied on a bending process using individual hydraulic presses, which were carefully operated to avoid visible press marks on the final bridge construction, which would be easily discernible on the smooth surfaces. To that end, bending was executed in small increments using small presses, with tolerances limited to a few millimeters to ensure structural integrity and prevent plate buckling.

EllisDon was the construction manager, overseeing the process from fabrication to erection. Dartmouth, Nova Scotia-based fabricator Cherubini also contributed to the steel fabrication, and Harbourside Engineering led the erection engineering for the bridges.

Following shipment of the plates from CIG’s Netherlands facility to Cherubini’s shop in Halifax, Nova Scotia, the bridges were fully assembled, minimizing on-site work and maximizing accuracy. The girder box and cross beams were fabricated in accordance with applicable Canadian codes of practice, with all joints welded for enhanced structural performance and a seamless visual appearance.

Successful realization

Once assembled, the bridges were painted and transported via barge on the St. Lawrence River to their designated locations in the Toronto Port Lands. Using a barge, each bridge was rotated into the correct position and lowered directly onto previously constructed abutments. Since two bridges span the newly created riverbed, the construction of the foundations and piers was completed in a dry environment before the riverbed was flooded. The final step of the construction process was pouring the concrete deck to complete the structural system.

The bridges are complete and open to the public. The surrounding park landscape, which is anticipated to be finished in 2025, will enhance the overall experience. The successful realization of this infrastructure project stands as a testament to the collaborative efforts of the design and construction teams, enriching the cityscape and facilitating community connectivity.

Matthias Peltz, P.E., is a structural engineer in schlaich bergermann partner’s New York City office, and Michael Stein, P.E., M.ASCE, is the managing director of sbp’s New York City and Los Angeles offices and a member of the board.

This article is published by Civil Engineering Online.