By Leslie Nemo

In the 1890s, New York City had the most extensive mass transit infrastructure in the world, but it was not enough to serve the city’s needs. The 496 mi of elevated rails and dedicated horse-drawn carriage tracks were crowded due to a booming population that rose from 33,131 to 813,699 between 1790 and 1860, according to Edward L. Glaeser in Urban Colossus: Why Is New York America’s Largest City? If New York were to better ferry its growing population around, it needed a transit system that avoided the streets entirely.

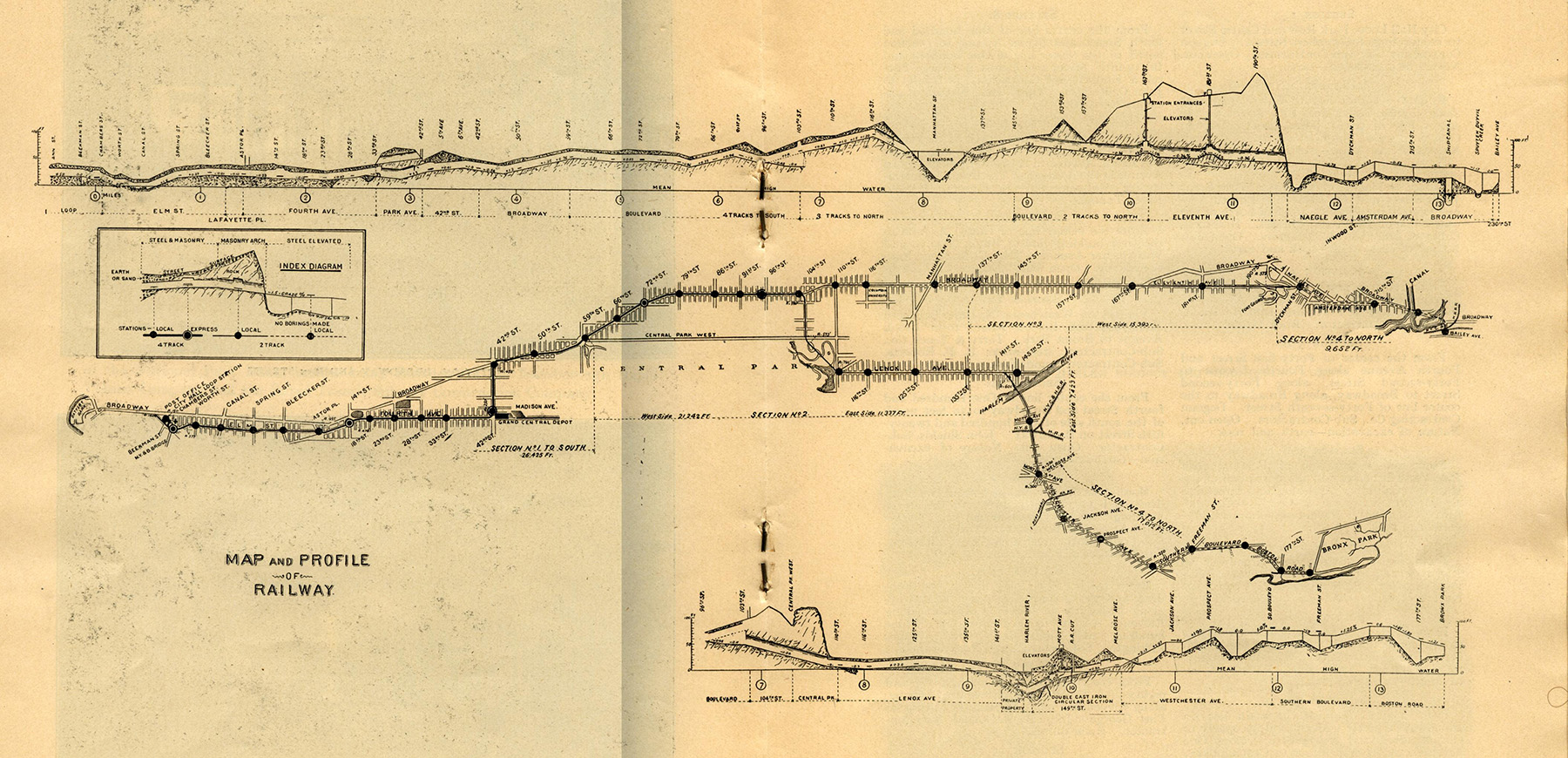

The first New York City subway met those requirements when it opened in 1904. Largely below ground, the nearly 20 mi of train routes made for the single-longest stretch of subway built in the world at that time. According to the NYC Landmarks Preservation Commission’s report Interborough Rapid Transit Company Powerhouse, the route was a “single line beginning at City Hall, then turning westward at 42nd Street to Longacre (now Times) Square, and proceeding northward through the Upper West Side to 96th Street. There the line split into two branches, one along Broadway, and the other beneath Lenox Avenue, with both terminating in the Bronx.”

Innovative construction brought the rail to life, all while allowing the city’s utilities, roads, and services to continue above ground mostly uninterrupted.

In 1863, London opened the world’s first underground city railway, known as the Metropolitan Railway. For the next 30 years, New York rail companies and businesses tried to replicate this effort without success. American inventor Alfred Ely Beach made the most progress. In 1870, he built a pneumatic subway that traveled a single block under Broadway. The build was illegal, and it never made it past the prototype stage.

It was not until 1891 that the state legislature passed the Rapid Transit Act, which allowed the Board of Rapid Transit Railroad Commissioners to design a subway system and secure rights of way from local authorities and adjacent property owners. Although the local authorities agreed to the plans, the property owners did not. Instead the Supreme Court of the State of New York approved the plans. When the commission put out a request for bids for a privately owned system, however, no viable bids came in, according to Interborough Rapid Transit / The New York Subway: Its Construction and Equipment by the Interborough Rapid Transit Co.

A stumped board of commissioners turned to an idea championed years earlier by Mayor Abram S. Hewitt: municipal ownership. He proposed that the city would fund and own a transit system while a private entity would build and operate it. When the city put the “Hewitt Formula” to a vote in 1894, it passed.

A second request for bids issued in November 1899 under the 1891 act stipulated the city would pay $35 million for construction of the system and an amount not to exceed $2.75 million for “terminals, station sites, and other purposes” and allowed 4 1/2 years for construction, per the IRT book. While the builder would lease the subway for 50 years, it ultimately belonged to the city.

One bidder was John B. McDonald. An Irish immigrant, McDonald worked his way up through various engineering jobs, and by 1894, he had completed construction on a railroad tunnel under the Patapsco River in Baltimore, the first “major underground electric railroad” completed in the Western Hemisphere, according to Clifton Hood in 722 Miles: The Building of the Subways and How They Transformed New York.

Wanting to accept McDonald’s bid, the city required that he pay $1 million in cash upfront as security for construction and $6 million in surety bonds for construction, equipment, and “continuing security for the performance of the contract,” per the IRT book. McDonald turned to August Belmont Jr., the heir to a banking empire, for help.

Belmont petitioned the board for a single incorporated company that could provide capital, security, and project supervision. This was ultimately approved, leading to the Rapid Transit Subway Construction Co. executing its contract with the city on Feb. 21, 1900. Later, Belmont would split off the operational side of the business into the Interborough Rapid Transit Co., the name by which the subway was eventually known.

When workers broke ground on March 24, they largely followed the specifications laid out by William Barclay Parsons (founder of Parsons Brinckerhoff). Hired as the board’s chief engineer in 1894, the 35-year-old had already drafted some ideas about how the tunnels should be built, having worked on the project when the commission assumed it would be privately held.

Walking crucial parts of the possible route and assessing the land, Parsons discovered that the bedrock — known as Manhattan schist — fluctuated in depth over its length. The schist rose to within 20 ft of the surface at its most southern tip, dropped to 163 ft in today’s Tribeca neighborhood, and stayed low before rising to 16 ft at 30th Street, according to Hood.

The changing schist levels led Parsons to argue for a shallow cut-and-cover approach, keeping the trains as close to street level as possible to avoid excavating rock for most of the route.

A trip to London; Liverpool, England; Glasgow, Scotland; and Paris to see how those cities constructed their subways pushed Parsons to suggest two additional design choices: electric train cars powered by a third rail and an express track that would allow some trains to skip stations.

Roughly a quarter of the IRT line ran through rock or concrete tunnels, while another quarter sat on elevated steel viaducts. The dominant design, however, covering 10.6 mi of the original subway distance, was what the IRT might call “typical subway.” Side walls are connected by vertical concrete arches and reinforced by I beams every 5 ft, the metal allowing the thickness of the siding to be “materially reduced,” per the IRT book. The tops of the I beams are connected by roof beams running the width of the ceiling. Between tracks, steel columns help hold up the roof beams, all structures resting on a concrete and cut stone base. To complete the top of the subway, workers placed concrete arches between the roof beams, according to the IRT book.

In most locations, under the concrete floor, behind the side walls, and between the roof and the street above, workers laid multiple layers of asphalt-washed felt as a kind of waterproofing. In other locations, “the felt waterproofing has been made more effective by one or two courses of hard-burned brick laid in hot asphalt, after the manner sometimes employed in constructing the linings of reservoirs of waterworks,” according to the IRT book. In one short stretch on Lenox Avenue, the “typical subway” walls became reinforced concrete.

How crews built this interior depended on the surrounding environment along the alignment, as existing water and gas mains, sewers, and electrical ducts snaked through the subway’s path. There were also pneumatic tubes for mail operated by the postal service that could not be moved as any glitch in the system “would have stopped the service,” according to the IRT book. Above ground, pedestrian and cart traffic could not be interrupted nor could trolley service. Designs also had to account for the elevated rail infrastructure that the IRT leased to become part of its operations.

For instance, above a stretch of track known today as the 6 train was a road with two “electric conduit railway tracks” at its center, per the IRT book. To keep the above-ground electric lines operating, workers sank a series of 8 ft by 10 ft wooden shafts along the perimeter of the road. From the ends of these shafts, workers made tunnels that eventually turned inward and ended 3.5 ft past the street centerline. Workers poured concrete on the tunnel bottoms, and after it cured they built wooden trestles atop the concrete. Concrete foundations in the tunnels and interior trestles let workers excavate between the wooden structures.

A gap between the electric train car tracks gave crews space to dig a long, slim trench between them, reaching a depth level with the tops of the underground trestles. With steel bars running the length of the trench and resting on the trestles, “the equivalent of a bridge was put up, the trestles acting as piers and the beams as girders,” according to the IRT book. Suspended, the electric trains continued operating as workers dug out the rest of the ground underneath them.

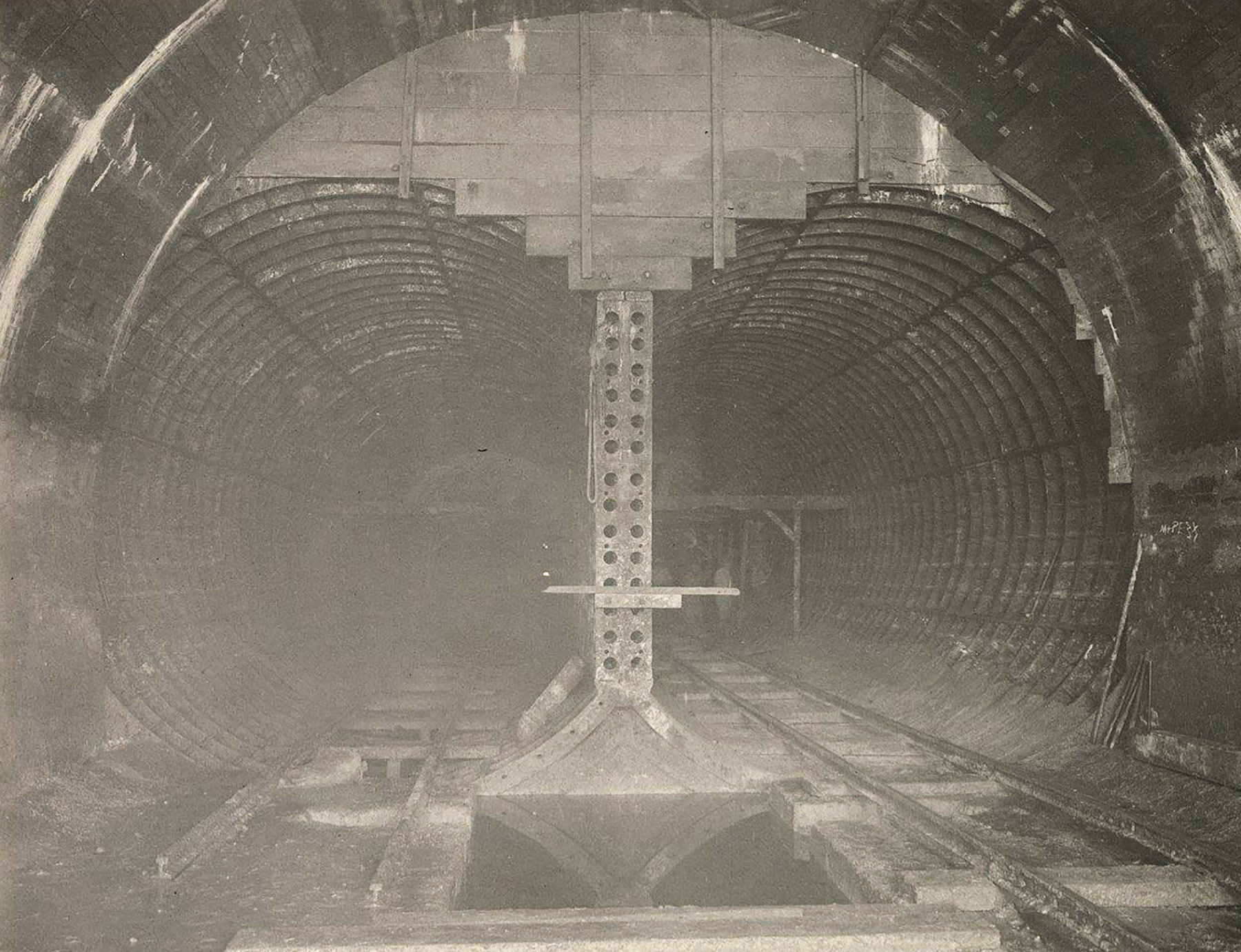

Efforts to keep surface-level life running smoothly extended to construction below the Harlem River. The War Department had two requirements for this area: “a minimum depth of 20 feet in the river at low tide, which fixed the elevation of the roof of the submerged part of the tunnel” and no more than half the 8 mi long river could be closed at a time, according to the IRT book. As a result of this last requirement, the work to build out twin 16 ft diameter, 641 ft long cylinders was done in stages: the west section first followed by the east.

The conditions were what would be expected in a river: a mixture of sand, mud, and silt, “much of which was so nearly in a fluid condition that it was removed by means of a jet,” according to the IRT book. For the west section approach, workers dug a 50 ft wide trench across where the subway would eventually rest. The trench was about 39 ft below the waterline, which was approximately “10 feet above the subgrade of the tunnel,” the IRT book states.

Starting from the western bank, workers built wharves — by installing three rows of piles on either side of the trench and adding platforms on top of the piles — that reached from the shore to the center of the river. Piles, in a grid measuring 6 ft, 4 in. by 8 ft between posts, were driven where the subway would be. The next step was to “cut off” the piles at 11 ft “above the center line of each tube and (cap them) with timbers 12 inches square,” per the IRT book. Connected trusses were floated over the piles and then sunk onto them.

Gaps between longitudinal pieces of wood holding the framework of trusses together allowed workers to drive 12 in. sheet piles into the earth about 10-15 ft lower than the base of the finished tunnel. When capped with a timber roof, covered with earth, and braced with sheet piles on the sides and ends, the wooden structure became a caisson. Workers excavated within the pressurized space before inserting a concrete and iron lining.

To construct the eastern bank, the process was similar except for the caisson. “Instead of using a temporary timber roof on the side walls, the permanent iron and concrete upper half of the tunnels was employed as a roof for the caisson,” the IRT book states. After workers sank the subway roof, an opening let a diver connect the half-tunnel to the shore, allowing more workers to come through and continue construction. Workers repeated the caisson-sinking technique three times to merge the subway stemming from the eastern side of the river with the portion already waiting on the western shore. Combined with concrete arched structures for approaches on either side of the river, the stretch of Harlem River construction was ultimately 1,500 ft.

Though the contract stipulated that work proceed via cut-and-cover where possible, four sections required tunneling through rock instead. In one section — from Broadway and 103rd Street to Lenox Avenue and 110th Street under Central Park — night workers used percussion drills to dig dual shafts and a portal through micaceous rock to carve the tunnels that would eventually contain parallel tracks. Workers carved top headings first, followed by two full-width benches. Their daytime colleagues removed the rubble, which was subsequently crushed for concrete that lined the tunnels themselves.

From 34th to 41st streets in the Park Avenue section, workers cut two parallel double-track tunnels underneath existing double-track electric railway tunnels. Work proceeded from a shaft at the end of each tunnel. Each approach proceeded with top headings on the northern ends of both tunnels and bottom headings on the southern ends of both tunnels.

One portion — built via two portal headings and two shafts — made for the second-longest rock tunnel in the United States after the Hoosac Tunnel in Massachusetts, running from 157th Street up until about 190th Street in Fort George. The work was deep and extensive enough that it attracted professional miners who migrated from around the world for different jobs. These workers were also involved in the most deadly incident during the project. In the Fort George neighborhood, the schist was angled and conditions were perfect for a rock slide.

Contractor L.B. McCabe & Sons — one of 15 firms assigned individual stretches of construction — increased the number of dynamite detonations in the tunnel from two to three per day to finish excavation before the tunnel was “holed through,” writes Hood. On Oct. 24, 1903, the foreman, thinking the blast site was stable, motioned to workers to move forward to clear the rock just before a 300-ton boulder dropped from above. The accident killed six immediately and injured eight; four of the survivors eventually died from their injuries.

Elsewhere, other contractors and crews built four viaducts for above-ground operations, one of which stretches over the Manhattan Valley. The structure here comprises three components: the viaduct itself, its masonry approaches, and the center multiribbed steel arch span, as described in The New York Rapid Transit Decision of 1900: Economy, Society, Politics by historian Wallace B. Katz for the Historic American Engineering Record.

To map out the viaduct’s path, workers built embankments supported by brick and granite block retaining walls. The viaduct itself is composed of double-bent steel towers spanned by plate girders, a structure the contractor built via an erecting traveler. The central arch — with ends supported by six concrete piers reaching 30 ft below ground — went in last. Workers connected the halves of each semicircle on the ground before lifting them into place with the erecting traveler and derricks. “The truss bracing of the arch ribs created fourteen panels of equal length and from each panel point a column rose to carry the floor system upon which the track and station were built,” per the HAER report.

Work also moved forward on the power station, known as the Interborough Rapid Transit Co. Powerhouse, a building destined to consume the length of an entire block in the city’s Hell’s Kitchen neighborhood. Conveyor belts carried barge-delivered coal to boilers, whose steam fueled the generators. Built to power up to 800 train cars simultaneously, the alternating current output made it the world’s largest electricity-generating station at the time, according to the NYC Landmarks Preservation Commission’s report.

Tackling the project was chief engineer S.L.F. Deyo, construction engineer John Van Vleck, electrical engineer Lewis B. Stillwell, and more than 400 workers. Besides the steel skeleton and the self-supporting granite steel walls of the facility, workers built chimneys and even a railroad spur and portals for freight trains coming through the eastern end of the building.

The city’s Department of Docks and Ferries constructed a wall along the Hudson River and a 700 ft long pier to receive coal shipments. The IRT laborers cut, via open trench, a 10 ft by 8.5 ft oval tunnel through the river wall that extended to the eastern edge of the facility for cooling water intake. A horseshoe-shaped conduit on top of the intake tunnel carried out hot discharge water, which was kept from mingling with cold water, thanks to two timber conduits that flared out on either side of the intake tube. In 1904, Parsons gave ASCE members the first tour of the place.

When the IRT opened for service to the public on Oct. 27, 1904, at 7 p.m., the city made it a party. That weekend, people waited in lines two blocks long for their turn to move underground at 40 mph. Not all the subway was operating — the section that extended under the Harlem River did not carry passengers for another month — but the IRT was already expanding in a second construction contract that would eventually carry people into Brooklyn and other parts of Manhattan. Even with only partial service, the subway reached its capacity of 600,000 passengers per day by October 1905, according to Hood.

The trains, particularly service on the express tracks, encouraged residents to shift their lives further uptown just as Hewitt hoped. From 1905 to 1920, the population of the area, including Harlem and nearby areas, grew 265%, while the Bronx population grew 150%, per Hood.

ASCE, in conjunction with the American Society of Mechanical Engineers, designated the First New York Subway as a joint national Historic Civil and Mechanical Engineering Landmark in 1977.

Leslie Nemo is a journalist based in Brooklyn, New York, who writes about science, culture, and the environment.

This article first appeared in the May/June 2024 issue of Civil Engineering as “The NY Subway Delivers Speed.”