By Leslie Nemo

From the Eiffel Tower to the Ferris wheel, world’s fairs are known for turning out memorable engineering achievements. Completed in December 1961 at a cost of $4.5 million, the Space Needle in Seattle joined the ranks of notable exhibition structures too, but just barely: Final designs and funding came through just 13 months before the fair was scheduled to open in April 1962.

It took about eight months from groundbreaking to torch installation for the Space Needle to be built, and once completed it was the tallest structure west of the Mississippi at that time. For visitors, the Needle offered “a chance to enjoy the scenic wonders of the Seattle area,” according to the official press booklet of the Seattle World’s Fair. For local engineers, fabricators, and architects, however, it offered a chance to see how far steel could take them.

Seattle was less than 50 years out from the Alaska-Yukon-Pacific Exposition — its first international event of this type, which ran during the summer and fall of 1909 — when city representatives started stirring for another one. City councilman Al Rochester voiced his desire for a world’s fair, and he persuaded the Washington state legislature to form a commission that would study this possibility. To head the commission, in February 1955, then-governor Arthur B. Langlie turned to Edward Carlson, his fraternity brother at the University of Washington and a Seattle-based hotel executive.

To become an official world’s fair, the event needed certification from the Bureau International des Expositions as well as a theme. The city wanted to host an event that would promote science and technology, and the commission decided on the “Century 21 Exposition” theme, which would showcase “modern science, space exploration, and the progressive future,” according to a web page from the Seattle Municipal Archives.

And if the sights and displays of the fair needed to be futuristic, then the architecture had to be, too. Paul Thiry, a leader of the architectural modernism movement in the Pacific Northwest and the chief architect of the exposition, knew the fair needed a single, standout feature. A handful of ideas came and went before luck struck. Carlson and his wife Nell joined family friends on vacation in Europe in the summer of 1959, and one evening he found himself in a restaurant on top of Stuttgart TV tower in Germany. Inspired, Carlson sketched a skinny tower on a paper placemat. He dubbed it the “Space Needle.”

Once back in the U.S., Carlson and the commission approached the Seattle-based architecture firm John Graham and Co. for sketches for a tower based on Carlson’s initial idea.

Through 1959, Graham, his team, and different fair representatives considered designs and possible attractions, such as a planetarium within the tower that would not only survive the fair but also provide a source of revenue.

The fair itself was expensive, so ideally, the tower should pay for itself.

Certification from the international bureau materialized in 1960, as did the Needle’s final design, when Graham and Co. contacted Victor Steinbrueck, an architect and professor at the University of Washington, in June. He too sketched a number of options.

One day in his home office he noticed a statue on display. Called The Feminine One and made by artist and friend David Lemon, the figure was an abstract rendition of a dancer reaching her arms above her head. Steinbrueck realized that a similar form — wide “legs” that taper to a waist before stretching out again (the “arms”) to support a saucer-like viewing area — could work for the Space Needle.

Despite this clearer idea of what would be built, the summer ended without finalized investors or a set location. The exposition site occupied 28 acres acquired by the city via condemnation for the purpose of a civic center.

If the Needle were to be privately owned, it had to be built somewhere else to avoid land-use lawsuits. The answer was an adjacent 120 ft by 120 ft plot, upon which was a city fire station that would have to be moved anyway.

In January 1961, geotechnical engineers conducted a field investigation program and found “firmly compacted” glacial soil, an appropriate foundation for the tower, according to Harold Mansfield in his book Space Needle USA. Since the Space Needle still did not have financing, Graham’s firm offered to buy the plot from the city, but in March, the Bank of California agreed to a loan, triggering other lenders to follow suit.

Eventually, a team of backers known as the Pentagram Corp. was formed: Graham; investor and real estate developer Bagley Wright; Howard S. Wright, the head of his own construction company and general contractor for the project; philanthropist and shipping heir David E. “Ned” Skinner; and timber industry executive Norton Clapp.

Meanwhile, John Minasian, P.E., a consulting structural engineer in California, was approached to bring his expertise to the Needle’s design. Minasian, who ended up serving as chief engineer for the project, confirmed the tower’s support was sufficient by working with academics and city and contractor engineers, like those employed by Graham and Pacific Car and Foundry Co., the steel fabricator for the job. The structure was designed to withstand 50% stronger winds and have double the earthquake resistance mandated by city code, which required “beefing up the structure all through,” according to Mansfield.

Minasian also wanted a model of the structure to pass wind tunnel tests, which it did at the nearby University of Washington.

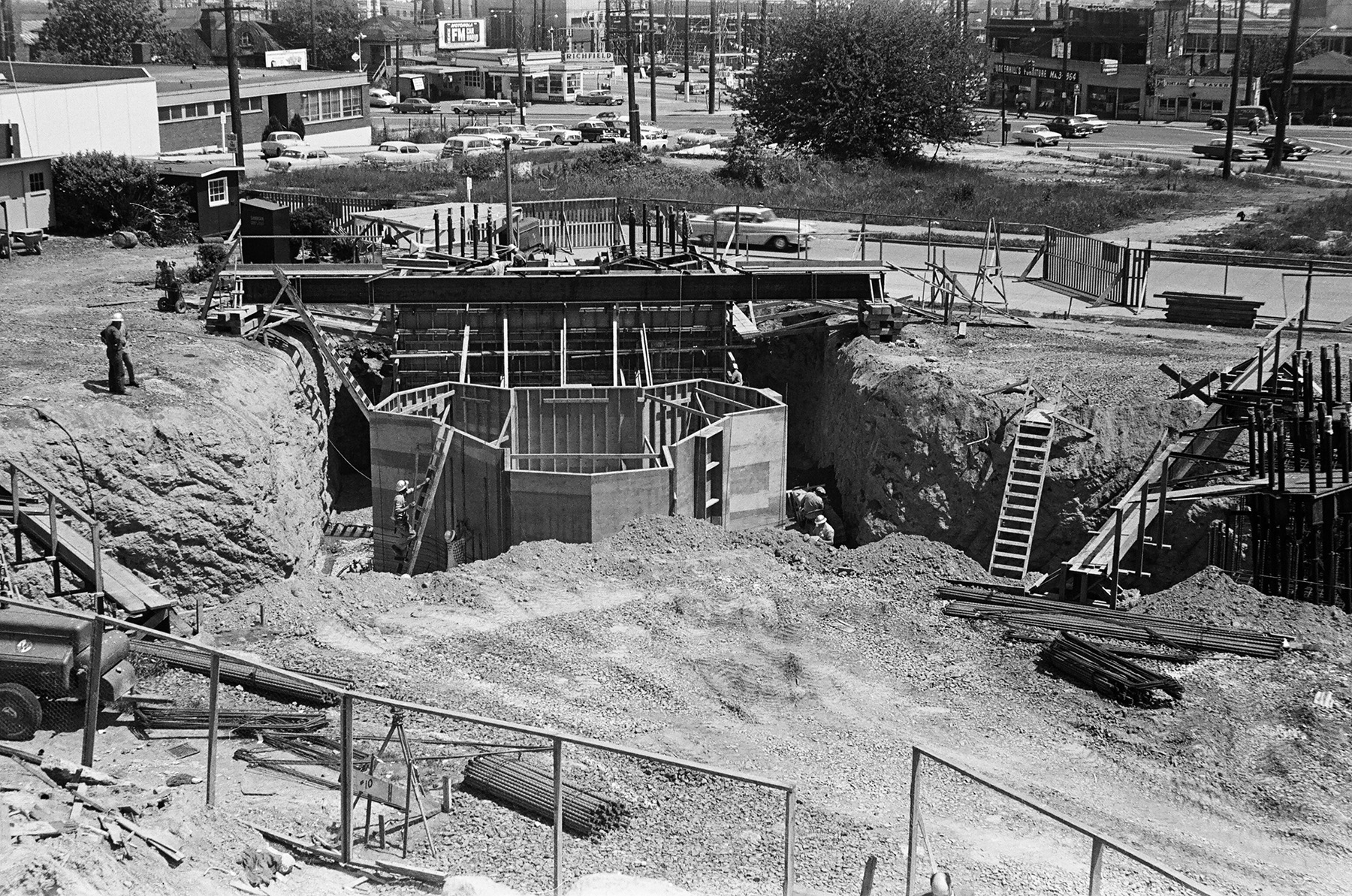

With Needle plans financed and the structure deemed sound, foundation excavation began on April 17 — just over a year before the fair was set to open its doors. Howard S. Wright Construction workers carved out a 30 ft deep, Y-shaped pit, with each arm of the Y becoming the location for the foundations for the Needle’s three columns.

Next, workers constructed the concrete foundations using 250 tons of steel reinforcing bar and 72 steel anchor bolts 31.5 ft long and 4 in. in diameter. (A fourth foundation for the Needle’s core used another 24 anchor bolts 10 ft long and 3 in. in diameter.) For 12 straight hours, 467 concrete ready-mix trucks delivered 2,800 cu yd of concrete, making for the “largest continuous building concrete pour in the West,” according to a Special Report on the construction from United States Steel.

The ASTM A36 steel components, which Minasian had ordered from the U.S. Steel catalog, allowed for “higher design stresses, welded fabrication, and (greater) cost savings,” per the Special Report. The steel components were shipped from Chicago to Pacific Car and Foundry in Renton, Washington, before the team transferred the steel to the site during morning deliveries.

Core installation happened first. The Needle’s central shaft comprised “vertical sections of bridge-like steel truss work,” according to Mansfield. “Three of these trusses, up each of which would ultimately run an outward-facing elevator, would be connected together with short horizontal pieces, making a six-sided shape.”

The first vertical installation was three trussed sections of the core. Only after a second round of core trusswork had been welded on top of the base core truss did the workers start installing the lower column segments. First, column base assemblies were lowered over the anchor bolts to rest on the concrete foundations.

Next came the column segments themselves, which were 90 ft long and weighed up to 90,000 lb. Each column connected to the foundation in two places, while each connection point comprised three 36 in. wide flange beams “welded together flange-to-flange and stiffened with diaphragms to form large, three-sided tubes,” per the Special Report.

The earliest phases of foundation construction and steel erection relied on a tracked mobile crane, but once this crane reached its lifting height limit (68 ft), it was used to erect the components of a fixed derrick crane which was mounted on a movable platform within the Needle’s 11 ft hollow core. Designed by Pacific Car and Foundry, it was capable of a full 360-degree swing to lift core pieces and column segments. Once the derrick crane had boxed itself in with successive core sections, it and its support platform were lifted by ground winch to a higher level within the core where the steel erection could continue.

As column segments were lifted into place, a waiting ironworker — sitting on an 18 in. long piece of metal stuck into a splice plate hole — would catch the leg with a spud wrench as a leg swung by and hammer in six drift pins to temporarily hold the piece in place, according to Mansfield. The merging was orchestrated by signalman Jim Torrey, who radioed instructions to the crane operator who was watching construction from above from a temporary wooden platform tied to the Needle core.

Later, a team of 39 welders would strengthen the connections, ultimately using “35.9 pounds of welding rod per ton of steel and 20.5 bolts per ton of steel,” according to the article “Speed and Safety Win in Needle Race,” which appeared in the spring 1962 issue of Washington Safety Advocate. After each day’s work, colleagues followed up with X-ray devices to ensure the welded connections were sound. The steel workers earned about $4 an hour, and none lost their lives on the job — despite having no harnesses or any other safety equipment on-site.

The columns first connected with the central core itself at the 100 ft level with three 30 ft long and three much shorter tie beams, which were, according to Mansfield, “box steel girder(s) with five-foot-high walls.” Another round of shorter steel tie beams went in at the 200 ft level as the columns grew taller and closer to the central core.

Between the 260 ft and 420 ft levels, each pair of columns “has a steel plate shirtwaist,” which, according to the January 1962 issue of Modern Steel Construction, made it look like the columns were one continuous piece. Up to the 400 ft level, each of the six columns was formed from three 36 in. wide flange sections, but after this point, each column comprised two sections.

At about 373 ft, the design called for a tapered waist. To make that happen, the steel columns would have to curve inward. Unsure of how to force the steel to bend, the Pacific Car and Foundry team took inspiration from a fire at McChord Air Force Base near Tacoma, Washington. The flames bent steel roof trusses, and to re-straighten them, workers used torches to mold them back into shape.

To pull off a similar feat for the Space Needle, foundry workers heated pie-shaped sections of the leg beams. As these sections cooled, the steel constricted, with greater contraction at the wider parts where the heat was applied, making the beams curve.

Column construction wrapped up, allowing for work on the saucer-like top to begin. The derrick crane first lifted into position 20-ton steel ring girder segments, outfitted with radiating beams or “fins” to create a “sunburst” effect. Each girder segment stretched from one leg tip to the next leg tip. Next came the steel for the restaurant’s floor, followed by a second ring girder extending 9 ft out from the Needle’s center to support the observation deck.

When it came time to install the “halo,” a ring hovering around the halfway height of the saucer, the reach was outside the range of the derrick crane. The halo was composed of steel outrigger pieces or ribs, which were described by Mansfield as downward-sloping “6-inch sparrow’s walkways into outer space.” To install the ribs, workers had to sit on them and slide the 9 ft long, 75 lb steel segments into place by hand. When completed, a revolving restaurant, mezzanine, observation deck, equipment room, and elevator “penthouse” amounted to a five-story building.

Above the halo, workers added a “pagoda-like roof of inward and then outward curve to enclose the top machinery,” creating a smaller third disk, per Mansfield.

On December 8, workers hoisted the last piece — the gas-powered torch tower (which has since been removed) — to the top. The 50 ft spire would bring the Needle to a height of 605 ft, but it first had to be “fastened off-center on a temporary rack,” per Mansfield, so that the derrick crane could come down, as it occupied the core’s center. The machinery could not drop through the central shaft because staircases had been assembled in the crane’s wake.

Instead, the crane was lowered through a portal in the side of the core. Workers stopped assembling the stairs 50 ft below the level of the restaurant floor so that the crane could be dropped in far enough to give room for some minor disassembly. Then, a portion of the core intentionally left unwelded swung open for the crane components to be removed and lowered to the ground. With the torch in place, steel erection was complete.

Paul Collop, superintendent on the project, believed that the Space Needle was “the only major structure for Century 21 that was completed within the target date,” according to the February 1962 article “Space Needle contractors set construction records” in Pacific Builder and Engineer.

In March 1962, visitors were allowed to access the Needle ahead of the fair itself, waiting three hours in line to see the views. When the exposition finally opened the next month, even more people followed: 2.65 million attendees made their way into the Needle over the six-month-long fair, a full million more than was originally estimated.

The overall success of the project included some behind-the-scenes chaos. Zoning rules in the area included height restrictions that the Needle had to be exempted from. Though the city council approved the project, the planning commission rejected the height-exemption request, so construction moved forward without the proper permits.

The question over who could take credit for designing the Space Needle also turned into a fight between Steinbrueck and Graham. In 1961, Graham and Co. filed an official complaint against Steinbrueck to the Washington State Chapter of the American Institute of Architects over the way the latter had taken credit for the Needle design.

Despite some early turmoil, the Space Needle has cemented itself as an iconic part of Seattle and its skyline. Massive renovations completed in 2018 added extra viewing space, giving visitors even better views of the city as it continues growing (mostly) beneath them.

Leslie Nemo is a journalist based in Brooklyn, New York, who writes about science, culture, and the environment.

This article first appeared in the July/August 2024 issue of Civil Engineering as “The Space Needle Takes Steel Skyward.”